Renishaw’s

Renishaw’s RenAM 500 series of metal additive manufacturing systems and its TEMPUS technology have been integrated into

Dassault Systèmes’ 3DEXPERIENCE virtual-machine environment. This integration allows users of the DELMIA powder bed machine programmer role to set up, program and analyse additive manufacturing (AM) processes for Renishaw systems in a fully interactive 3-D environment.

Jérémy Mosse, team and application manager at

discover.3ds.com Dassault Systèmes, said: “A virtual machine is an exact representation of a machine in the virtual world, with all its parameters. You can launch a production run and make virtual parts — it is unique in terms of quality validation.”

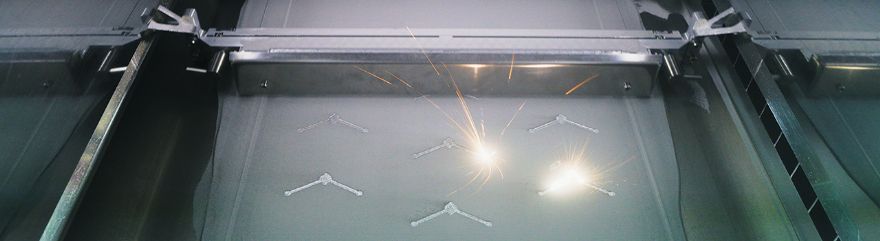

The collaboration includes Renishaw’s TEMPUS technology, an innovative scanning algorithm exclusive to the RenAM 500 series. TEMPUS enables the laser to operate while the recoater is in motion, saving up to nine seconds per build layer without compromising part quality. This breakthrough can reduce overall build times by as much as 50%, significantly improving productivity.

“This collaboration enables a unique approach to efficient metal 3D printing. The combination of Renishaw's TEMPUS technology and the end-to-end unique solution provided by the 3DEXPERIENCE platform will break silos and open a new stage for additive manufacturing industrialisation,” said Olivier Scart, DELMIA Alliances director partnerships at Dassault Systèmes. “Partnering with 3D printer manufacturers maximises efficiency by optimising build preparation and streamlining build jobs. This enables manufacturing at all volumes and levels of customisation, allowing users to scale production.”

Matt Parkes, AM strategic development manager at Renishaw, added: “This technology allows the lasers to work continuously while the recoater supplies and positions each layer of powder, significantly increasing productivity and reducing the manufacturing cost per part. With TEMPUS technology, Renishaw has successfully solved an inefficiency in the traditional laser powder bed fusion production process, and paved the way for AM use in a broad range of applications where it wasn’t previously cost effective.”

The partnership between Renishaw and Dassault Systèmes delivers an end-to-end solution that streamlines data collection and analysis, ensures certification and replication capabilities, and provides advanced simulation tools for part validation before 3-D printing. Manufacturers can now optimise build preparation, improve traceability and achieve faster production without compromising quality.