A manually operated CNC tube-bending machine from

Unison Ltd is set to assist

Leonardo in maintaining the operational readiness of AW101 Merlin helicopters at RNAS Culdrose in Cornwall. Yeovil-based Leonardo is the prime contractor for the UK Ministry of Defence’s Integrated Merlin Operational Support (IMOS) programme. Installed in April 2025, the Unison EvBend 1000 can bend aluminium and titanium tubing ranging from 6 to 18mm in diameter, with wall thicknesses from 0.5 to 1mm. These parts will be used in the aircraft’s hydraulic system.

Shane Lovett, Leonardo technical support service manager – IMOS, said: “Our support contract for Merlin helicopters requires us to respond promptly to all MRO requirements relating to the Culdrose fleet. It’s reassuring to know that as a UK-based business, Unison will never be more than a phone call or short distance away should we need assistance or support.”

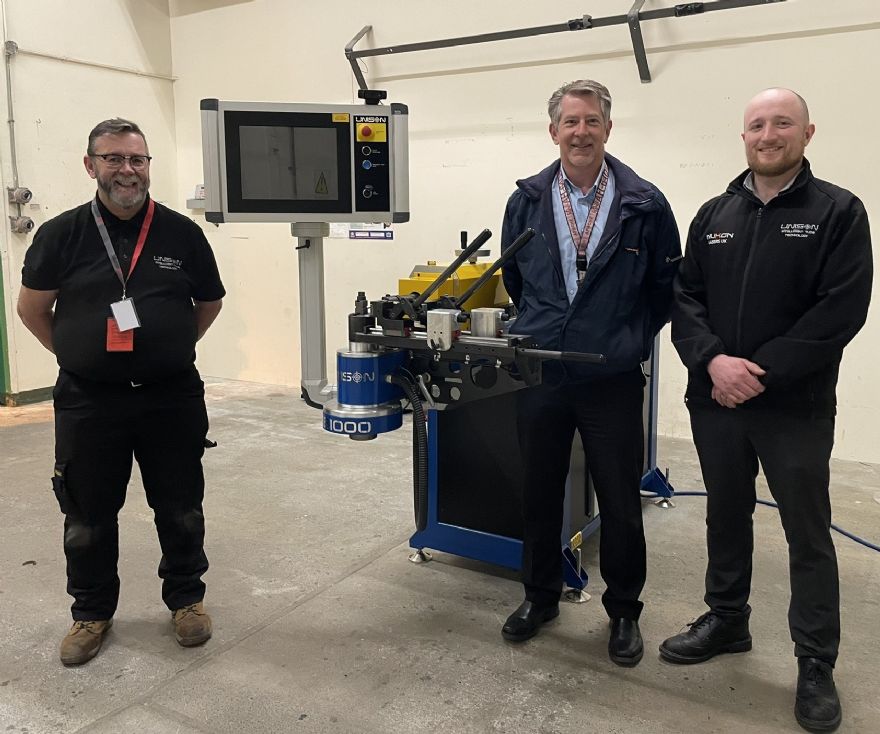

Factory acceptance testing of the EvBend 1000 took place at Unison’s Scarborough facility in March 2025, with installation at RNAS Culdrose a few weeks later. Simple to operate yet offering precise CNC control, the machine is already reducing the team’s reliance on external component suppliers.

Luke Gibson, UK sales manager at Unison, added: “Designed for low-volume, high-accuracy production and prototyping, our manually operated, CNC-controlled EvBend models are used widely across aerospace and MRO, Formula One and the oil and gas industry, where they provide three-axis mandrel, multi-plane bending at a fraction of the cost of fully automated machines.”

Unison also offers the larger EvBend 2000 model, capable of bending tube up to 50mm in diameter with servo-assisted functionality. Both models feature a 15in PC-based touchscreen CNC, capable of processing up to 100 bends per part, storing infinite parts, and connecting to CAD and most tube measuring systems.