Skiving is widely regarded as one of the most efficient methods for producing gear teeth, but it remains technically demanding. Tool specialist

LMT Tools, known for its innovation and customer focus, is simplifying the process with a new engineering portal designed to provide targeted support, minimise errors, save time, and ensure quality.

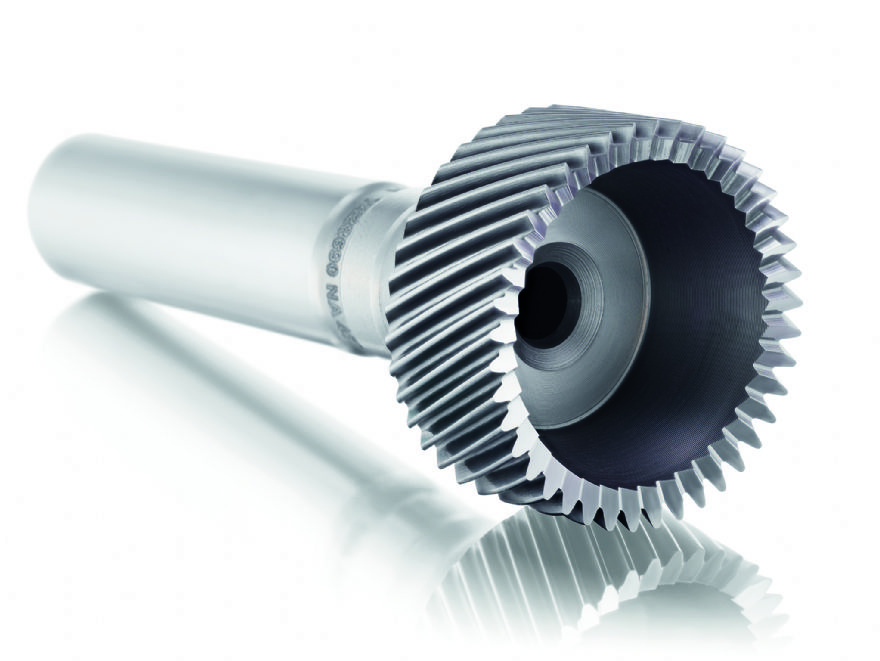

For gear skiving,

LMT Fette — a subsidiary of LMT Tools and the group’s gear cutting specialist — supplies high-performance tools that combine the latest research with proven application and manufacturing expertise. With their combination of cutting-edge preparation and individual process simulation, the skiving wheels set benchmarks for machining time, manufacturing costs, component quality, tool life, and process reliability, ensuring maximum performance in producing internal and external gears.

Each skiving cutter is unique, with cutting material, geometry, coating, and edge preparation tailored to the component and customer-specific process. Every tool is individually parameterised and calibrated on the machine, but these complex adjustments often challenge even experienced users. Deviations in measurement reports—whether during commissioning, after prolonged use, or following regrinding —typically require consultation with LMT Tools, costing valuable time.

Digital self-help toolThe new engineering portal changes this. Michel Matzen, development engineer at LMT Tools, said: “The engineering portal is designed as a digital self-help tool. We enable users to analyse deviations independently and correct them immediately without having to forego our expertise — quickly, easily, and without detours. This is uniquely worldwide in this form.”

After entering the material and serial number from the tool and the relevant measured values, the portal calculates correction values in seconds and provides clear adjustment instructions, including for the cross angle and kappa angle — two key parameters in roll forming. This transforms a complex correction process into a streamlined workflow. The application is deliberately designed to be simple and intuitive so that operators of all experience levels can use it confidently, a significant advantage given the shortage of skilled workers.

The portal is automatically available with every tool purchase and can be used immediately after a one-time online registration. Beyond calculating correction values, it offers cutting data, tool overviews, setting data sheets, drawings, and application aids — all accessible from any device. The benefits include time savings, autonomy, improved gear quality, and greater process reliability, leading to higher productivity and lower unit costs.

Mr Matzen concluded: “We see ourselves as partners to our customers and want to make working with our products as easy and efficient as possible. With the new digital engineering portal, we offer practical support and give users a decisive competitive edge.”

Currently, the portal focuses on roll forming but already includes ChamferCut and other tool families with further tools and services to follow.