The new Colchester Magnum HD, available from Elland-based

Colchester Machine Tool Solutions Ltd (CMTS), is a heavy-duty manual lathe designed for workshops handling large components. Continuing the brands long heritage in manual turning, the Magnum HD sits firmly in the large-capacity segment of its manual lathe range, by combining mechanical strength, smooth control, and straightforward usability. It is ideal for a range of sectors where power and precision must coexist, such as oil and gas, energy generation, transport, shipbuilding, and heavy fabrication.

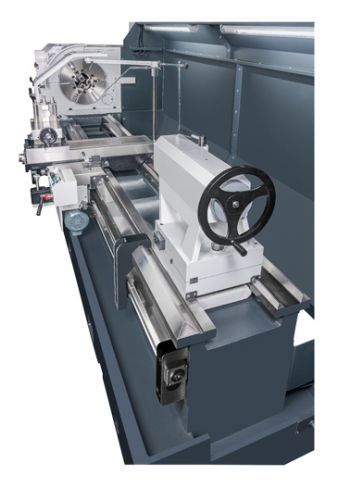

With a swing over bed of 800 or 1,000mm, capacities up to 8m between centres, and spindle bore options up to 380mm, the Magnum HD is capable of tackling components far beyond the reach of conventional manual lathes. Its single-piece cast-iron bed provides exceptional rigidity and vibration damping, ensuring consistent accuracy under heavy load and extended duty cycles.

Wide mix of workTypical headstock configurations offer spindle speed ranges from 4–800rev/min across multiple gear ranges, allowing slow, high-torque cutting for roughing and difficult materials, as well as higher speeds for finishing passes. This suits a wide mix of work in medium and high-strength steels, stainless steel and other alloy components commonly found in energy, oil and gas, and heavy engineering applications

Furthermore, the gearbox and headstock are arranged to provide smooth torque transfer at low speeds, helping the machine maintain stability and dimensional control when dealing with large, unbalanced or irregular-shaped workpieces. These characteristics make the Magnum HD particularly relevant for repair and maintenance work, heavy turning operations, and general-purpose machining, especially where large part envelopes, significant section thickness, or tougher materials place high demands on machine stiffness and drive performance.

The Magnum HD maintains Colchester’s tradition of ergonomic and practical design. The machine’s layout provides clear, unobstructed visibility of the cutting zone, helping operators maintain safe working practices and monitor tool engagement on large components. Controls are positioned for logical reach and intuitive use, reducing unnecessary movement during setup and machining. Despite its size, the lathe retains the tactile control and sensitivity that experienced machinists value in manual work.

Optional features such as digital readouts (DROs), taper turning attachments, and various toolpost configurations allow users to adapt the machine to their specific operational requirements. These options enhance usability without detracting from the straightforward, hands-on operation that defines Colchester’s manual range.

Built for accuracy and longevityColchester’s manual lathes have long been recognised for their mechanical reliability, and the Magnum HD is no different. Its hardened and ground bedways provide wear resistance on the primary sliding surfaces, while the machine’s precision-grade spindle bearings help minimise runout and vibration. Together, these features support stable cutting behaviour and maintainable accuracy over extended periods of use.

The machine’s single-piece bed casting also contributes to long-term alignment, helping the lathe retain geometry even under heavy loading or sustained duty. This is particularly important for workshops machining large-diameter or high-mass components, where bed stability directly influences surface finish and dimensional consistency.

Supported by Colchester’s UK-based service, parts, and technical support network, the Magnum HD offers long-term dependability and practical maintainability, both essential for industrial users.

While CNC machining dominates high-volume production, manual lathes like the Magnum HD continue to serve a critical function across manufacturing and the maintenance sectors. For one-off components, prototyping, and rework applications, manual machines provide the direct control and flexibility that automation cannot fully replace.