GrindingHub 2026

GrindingHub 2026 is set to showcase the very latest in grinding technology, with a strong emphasis on hybrid machining systems and cross-process efficiency. The event, taking place from 5 to 8 May 2026 in Stuttgart, will demonstrate how users can achieve higher material-removal rates, reduced downtime, and maximum process stability through cutting-edge processes. It promises to set a new benchmark for networked, resource-efficient, and high-precision manufacturing.

Tobias Trautmann, managing director of

Vollmer Werke Maschinenfabrik GmbH said: “Today’s tool manufacturers are striving for ever more efficient ways to produce their tools to customer specifications — and to do so on an automated basis. We support this goal with various sharpening technologies that can not only machine ultra-hard cutting materials precisely, but also optimise manufacturing processes thanks to digital solutions and AI applications.”

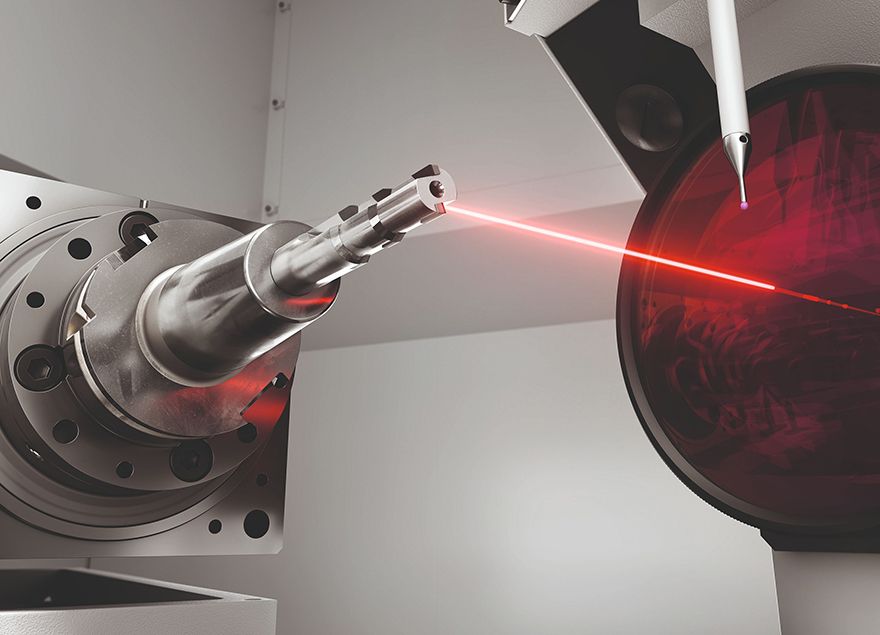

The Vollmer Group will present its range of grinding, eroding, and laser machines designed to handle ultra-hard cutting materials such as carbide, PCD (polycrystalline diamond), CVD diamond, and PcBN (polycrystalline cubic boron nitride). Hybrid machines are attracting particular interest for their ability to sharpen tools faster and with higher quality. For example, full-head PCD tools with complex geometries can be processed in a single clamping operation, with contours in the carbide ground and cutting edges in the PCD head eroded seamlessly. This approach shortens both productive and non-productive time while ensuring a smooth transition between the PCD head and the carbide blank without unevenness.

Grinding machines remain essential for sharpening cutting edges made of carbide or PcBN using diamond wheels. When grinding is not possible or only partially feasible, eroding or laser machines come into play. Lasers offer a distinct advantage over erosion by working on non-conductive materials, and because both eroding and lasering are contactless processes, they avoid the wear associated with grinding wheels and minimise thermal influence on the tool.

Digital solutionsAutomation is central to Vollmer’s philosophy. All machines are designed for 24/7 operation, supported by central robot systems that manage loading trolleys, pallet loaders, or chain magazines and oversee the fully automated machining process. Digital solutions are increasingly driving efficiency, with IoT (Internet of Things) gateways standard on Vollmer machines to enable seamless networking. Data from multiple machines is collected and managed via a central IT platform, while AI-powered algorithms and chatbots provide instant answers on machine utilisation, production volumes, and missing parts.

Vollmer Group’s managing director Ralf Grosshauser said: “To make our machines even more efficient, we collaborate intensively with customers, industry partners and research institutes. We work with

Furtwangen University on grinding technologies and belong to a network of around 30 companies that exchange knowledge and help each other stimulate future innovations.”

Studer’s WireDress technology exemplifies the intelligent integration of hybrid processes in grinding. Now available for both external and internal cylindrical grinding, this electro-erosive dressing system is fully integrated into CNC grinding machines, eliminating the need to dismantle and reset the grinding wheel manually.

Christoph Plüss, CTO of

United Machining Solutions Management AG in Switzerland, explained: “In the WireDress process, metal-bonded diamond or CBN grinding wheels are dressed, profiled and sharpened in the machine using a wire. The dressing process can be carried out at the full working speed of the grinding wheel. This massively reduces non-productive time. Especially when grinding high-alloy, hardened steels, carbides and ceramics, where metal-bonded grinding wheels are used, WireDress offers enormous advantages and provides productivity increases of up to 70 percent for certain materials when this technology is used.”

United Machining Solutions Group, which now includes 15 brands following its 2025 expansion, will also be present at

GrindingHub. With a turnover exceeding $1.5 billion, the group ranks among the world’s largest machine tool manufacturers and will be ready for in-depth discussions with visitors.

Hard skivingAfter hardening, internal gears can be finished using processes such as honing, profile grinding, generating grinding, hard skiving, or hard broaching, each with its own strengths and limitations. Hard skiving is highly cost-effective but falls short on precision, while profile grinding delivers maximum accuracy at the expense of speed and cost, limiting its appeal for high-volume production in sectors like e-mobility or commercial vehicles.

Liebherr-Verzahntechnik GmbH has bridged this gap with SkiveFinishing, a process that combines the kinematics of power skiving with a dressing-free, electroplated tool. The result is significantly higher quality than hard skiving, with shorter process times and lower costs than profile grinding. Haider Arroum, division and site manager tools said: “SkiveFinishing combines the flexibility of skiving with the advantages of CBN hard finishing. Optimal roughness values and economical processes can be achieved through the targeted selection of CBN grain sizes.”

Further efficiency gains come from twist-free generating grinding. Liebherr’s advancements in this area have brought machining times with dressable grinding worms close to conventional processes, even for asymmetrical gears. Optimised shift methods now allow fine grinding or polishing to be integrated into a single operation.

Suitable for applications ranging from e-mobility transmissions to heavy-duty gear systems, this technology offers measurable improvements in both precision and productivity. Fabian Stadelmann, technology development manager said: “In combination with the high rigidity of our machines — which our customers repeatedly praise — we offer measurable added value in terms of efficiency and precision and therefore a clear competitive advantage.”

Hybrid technologies are proving to be a major lever for companies seeking to lead in technology and profitability. The innovations highlighted here demonstrate the future direction of grinding technology. Combined with megatrends such as automation and artificial intelligence (AI), they open up countless opportunities to stay ahead in global competition. GrindingHub’s third edition will provide a unique platform to explore these developments and shape the roadmap for future innovations.