Tezmaksan Robot Technologies

Tezmaksan Robot Technologies has strengthened its long-standing relationship with

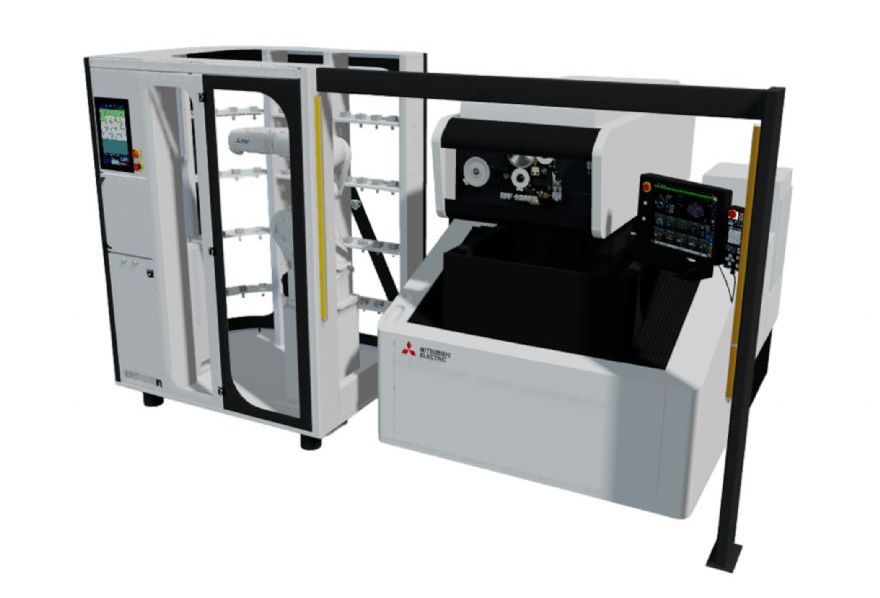

Mitsubishi Electric Europe through the launch of CubeBOX EDMCell, an automated system designed for wire Electrical Discharge Machining (EDM). The solution brings together Mitsubishi Electric’s established EDM technology with Tezmaksan’s CubeBOX automation platform to enable continuous, unmanned loading and unloading in a compact, modular format suited to modern production environments.

The partnership builds on more than 15 years of cooperation between the two companies. CubeBOX EDMCell integrates Tezmaksan’s automation capabilities with Mitsubishi Electric’s precision EDM systems to help manufacturers improve machine utilisation, reduce manual intervention and extend production hours without major alterations to existing plant layouts.

Mitsubishi Electric’s wire EDM machines are recognised for their accuracy and stable cutting performance, employing advanced wire control and servo systems to deliver fine surface finishes in hard or complex materials. Tezmaksan’s CubeBOX platform, already used widely for CNC machine tending, offers modular part handling and storage within a small footprint, allowing straightforward integration with a variety of machine tools.

By combining these technologies, CubeBOX EDMCell provides automated loading and unloading for wire EDM operations, enabling lights‑out running overnight and at weekends. Its modular design supports installation alongside existing machines, and the compact layout helps factories maximise limited floor space while maintaining the precision and repeatability required for complex or high‑accuracy components.

Practical automationHakan Aydogu, general manager at Tezmaksan said: “This collaboration focuses on practical automation that delivers measurable value to manufacturers. By combining our CubeBOX automation platform with Mitsubishi Electric’s EDM systems, we are creating a solution that improves efficiency, supports operators and maintains precision over long production runs.”

The first CubeBOX EDMCell was shown at last year’s

EMO Hannover 2025 as part of Tezmaksan’s wider automation offering. Aimed at facilities looking to raise capacity without increasing staffing levels, the system is designed for continuous operation with minimal oversight. Remote monitoring and diagnostic functions can be incorporated, helping to schedule maintenance, reduce downtime and improve production planning.

Mr Aydogu said: “Collaborations of this kind allow us to align automation capability with advanced EDM technology. Our objective is to make automated EDM accessible to a wider range of manufacturers and to support the transition to more efficient, data‑driven production.”

Tezmaksan and Mitsubishi Electric Europe intend to continue developing joint automation solutions that combine flexibility, reliability and high‑precision performance for a range of machining applications.