TaeguTec

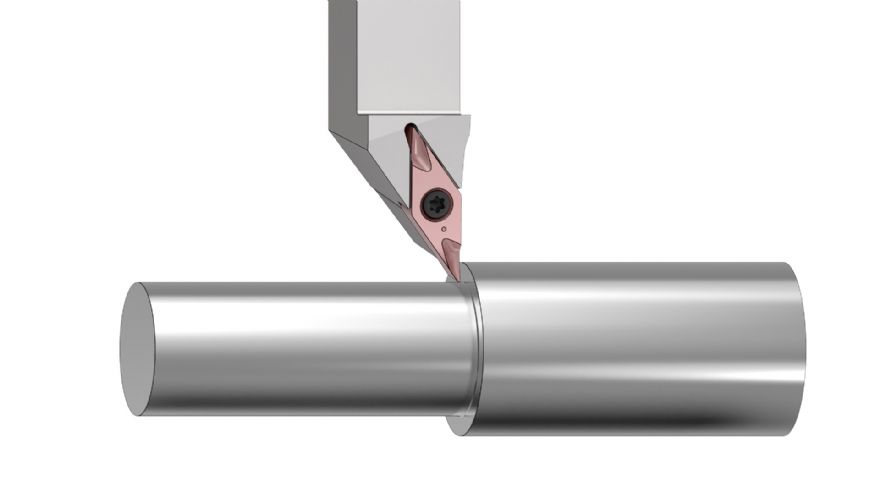

TaeguTec has expanded its Rhino‑Turn series with the introduction of the DNGX‑ST, a new four‑corner negative insert designed to advance heavy‑duty depth‑of‑cut turning, particularly within Swiss‑type machining. The company says the insert represents a significant step forward for users seeking higher productivity when machining small, complex components.

At the centre of the development is an enhanced chip‑breaker design that allows turning to depths of up to 5mm, a substantial capability for the small‑parts sector. By enabling such deep cuts, the insert reduces the number of passes typically required, offering clear productivity advantages. The insert incorporates a 30‑degree high‑rake geometry, which generates lower cutting forces and supports improved surface finish and extended tool life.

Chip control has also been a major focus. TaeguTec reports that the DNGX‑ST maintains stable, continuous chip formation across a wide range of cutting conditions, even at maximum depth. This consistency reduces cutting force fluctuations and makes the insert particularly well suited to modern sliding‑head machines, including those equipped with servo‑oscillation swarf‑breaking technology.

Compatibility with existing RHINO‑TURN holders allows users to adopt the new insert without additional investment in tooling. The DNGX‑ST is available in both micro‑honed and sharp‑edge versions, covering a spectrum of operations from fine finishing to more aggressive roughing work.

The double‑sided, four‑corner configuration provides a higher number of usable edges than earlier insert designs, offering both economic and operational benefits. Corner radii from 0.1 to 0.4mm accommodate applications requiring sharp detail as well as more robust machining, supported by a depth‑of‑cut range from 0.3 to 5mm. Feed rates from 0.03 to 0.12mm/rev further expand the insert’s suitability for machining carbon, alloy and stainless steels.

TaeguTec is offering the DNGX‑ST in its advanced PVD‑coated TT9020 and TT4430 grades, supporting a range of material and performance requirements.