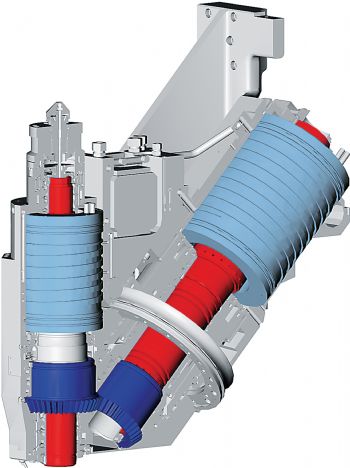

#tooling #manufacturing #engineering #VMCs The development by the Swiss company Reiden Technik of a hybrid dual-motor spindle assembly (DDT) for its range of vertical machining centres breaks new ground in process capability; the assembly can operate as a 27kW 291Nm high-torque spindle with a maximum speed of 3,000rev/min or as a 16,000rev/min 28kW (83Nm of torque) unit for fine finishing. Moreover, because both motors are within the same spindle housing, high-speed and high-power machining operations can be carried out in the same set-up, thus improving geometrical accuracy and reducing lead times.

This spindle allows Reiden machines — available in the UK from 2D CNC Machinery Ltd, Rushden

(www.2DCNC.co.uk) — with DDT to be used in a more ‘universal’ role. The two motors in the assembly are connected via a bevel-gear coupling arrangement and, according to the machine program, hydraulic power is used to either engage or disengage the higher-torque drive system, allowing the unused drive to ‘free-wheel’. The hybrid bearing system is hydraulically pre-loaded to support the higher torque, and the spindle head is water-cooled through a specially designed labyrinth of passages. The spindle arrangement has a through-tool coolant supply to maximise machining efficiency.

The DDT spindle assembly can be specified for Reiden’s RX10 five-axis universal machining centre, which features mineral castings for the bed and column, has a work envelope of 1,000 ¥ 1,100 ¥ 810mm, rapids of 40m/min, an acceleration of 7m/sec2 and direct measuring scales on each axis. That said, the vertical Z-axis cross beam has two linear measuring scales, one for each of the twin synchronised drives (master and slave), which use Heidenhain torque motors and ballscrew assemblies to power the vertical slide and position the DDT spindle assembly.

The C axis can revolve at up to 20rev/min. Control is by Heidenhain iTNC 530; Siemens 840D is an option, as are laser tool setting and tool breakage control, quick-change pallet systems and linear storage systems.