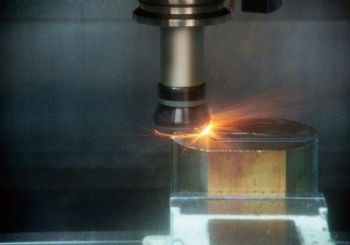

For the high-speed milling of difficult-to-cut materials, NTK (

www.ntkcuttingtools.co.uk) has now developed a new SX9 insert grade — the company’s toughest milling grade to date — that can operate at speeds greater than 800m/min.

Created for the machining of Inconel 706, 713 and 718, as well as difficult aerospace materials and ductile cast irons, this grade allows machining at higher feed rates and with greater depths of cut than previous ceramic grades.

Moreover, the composition of the new SX9 allows it to machine materials with tough and difficult-to-cut scale on the billet; and because it offers a high level of resistance to flank wear, it is also suitable for rough machining (the engineers at NTK have also developed inserts that allow SX9 to be used in turning-tool-holders with positive and

negative round inserts).

For milling, the round RNGN and RPGN inserts can be used, as can square SNGN, SNEN and SNGF inserts. The rectangular LNX and APCW inserts are for shell-, face- and end-milling cutters. For high-feed roughing, NTK recommends its XTM face-mill cutter body; this is available in diameters from 25 to 160mm and with two to 20 insert pockets (depending upon the diameter of the cutter body).

For higher-speed and higher-feed milling, the QTS shell mill is available with diameters from 40 to 125mm and with four to nine insert pockets.

The APCW inserts for the shell mill are also suitable for the new QTE end mill, which has a 16mm-diameter shank, diameters from 25 to 40mm, and two, three or four insert pockets.

To accommodate the round RNGN and RPGN inserts, NTK offers its RNIW shell mill cutter body, which is available in diameters from 32 to 125mm and with three to 12 insert pockets.