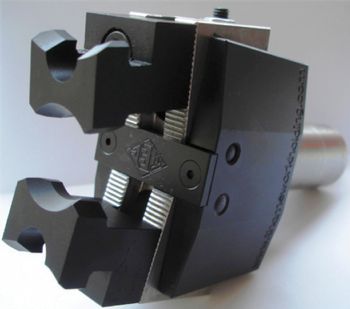

Designed to simply and cost-effectively increase the efficiency of CNC lathes and turning centres featuring a programmable tool turret with plain or VDI shanks, the Powerpull from Aylesbury-based Thame Workholding (

www.thameworkholding.com) is a two-jaw lever chuck with variable gripping pressure, allowing it to cater for most material types.

This bar puller is available in two body sizes covering bar diameters from 6 to 90mm, with one set of reversible jaws for bore clamping. Designed to pull bar stock and tube into position for CNC machining, the Powerpull supports unmanned working without the need for a bar feeder.

In operation, the bar stock is initially fed manually through the machine’s hollow spindle to a fixed stop for the first programmed machining cycle. For subsequent cycles, the Powerpull in the tool turret is advanced, forcing its spring-loaded jaws over the bar clamped in the spindle chuck. With the chuck released, the Powerpull allows the bar to be pulled out to a pre-determined stop position on the Z axis.

With the bar again clamped in the chuck, the turret is withdrawn further, overcoming the spring tension to release the jaws, leaving the bar ready for machining. This sequence is repeated until the batch is completed or the bar stock is depleted.