Enhanced programming software for five-axis and high-speed machining will be demonstrated by Birmingham-based Delcam plc (

www.delcam.com).

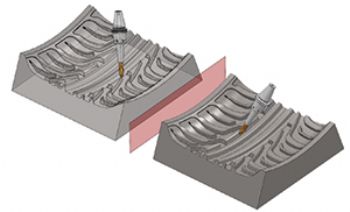

The main enhancement to the company’s PowerMill 2016 CAM system is the ability to mirror complete machining projects

in one operation, to automatically maintain the machining characteristics, and to automatically select whether to use climb milling or conventional milling. Previously, only individual tool-paths could be mirrored.

To ensure that the mirroring has performed as expected, the new option can undertake complete verification of a project for machine tool issues such as collisions, thereby ensuring that the machine tool is capable of running the mirrored tool-paths, as well as checking for both machine tool collisions and tooling collisions.

The latest version of PowerMill also introduces the ability to simulate machine tool movements as tool changes are undertaken, including the simulation of more-complex tool changes — in particular those involving carousel mechanisms.

Other improvements include: a new form to print out the position of the cutting-tool tip during simulation; an auto-translucency option that allows viewing of the ‘table-attach point’ at all times, and the ability to draw — translucently — the safe areas for rapid moves.(Hall 4, Stand C05)