Oldham-based GT Grinding (

www.gtrinding.co.uk) has invested in a Walter Helitronic Power tool grinder to meet demand for its products.

Supplied by Walter Ewag UK (part of the United Grinding Group), the new machine will be used to manufacture special-purpose tooling and to regrind tools for GT’s UK-wide customers.

Complementing three other Helitronic machines at the company’s facility, the new Helitronic Power is equipped with an Eco Loader and a wheel changer (as well as the latest version of Walter’s Tool Studio software) to ensure that GT “stays ahead in the design, modification and grinding of rotary tooling”, according to works manager Andy Cooper.

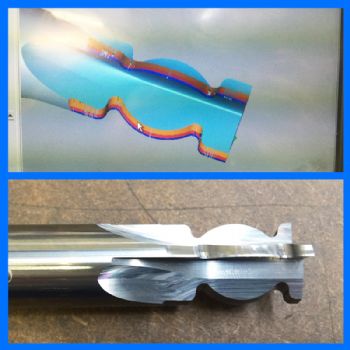

He said: “This latest machine will undoubtedly help us to make further inroads into our manufacturing and regrinding operation, especially of routers for the woodworking and plastics industries, and the Tool Studio 3 software will play a key role, too.”

It includes new routines for fast tool production simulation and parameter changes, plus the probing and alignment of asymmetrical flats; in-process wheel measurement inside the machine; core compensation for long tools; automatic

machine axis referencing; and coolant hole detection (by camera).

In addition, the tool grinder offers automatic non-stop production thanks to the Eco Loader, which can accommodate 20 tools as standard and up to 165 tools in the Eco Loader Plus configuration.

Mr Cooper says he has a long history of using Walter tool grinders — it goes back 30 years — and while he “visits the biennial i>

to keep track of all machine developments”, he always returns to Walter.