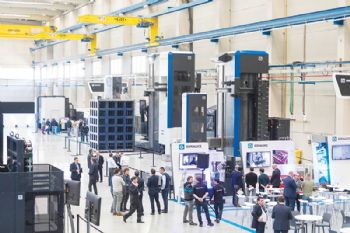

Soraluce’s official opening of a new factory dedicated to the assembly of portal-type machining centres took place during a three-day Portal Summit event that was attended by over 500 visitors.

The new facility, coupled with the launch of a new range of “redesigned and revitalised” machines, has reinforced the company’s leading position in portal-type machining technology.

Moreover, the latest developments designed to offer improved machining routines include milling, boring, turning and grinding in a single set-up were shown on a bed-type milling machine from the new Compact range.

In addition to new machines, Soraluce also demonstrated a range of “technology innovations”.

These included: the new DWS (Dynamic Workpiece Stabiliser) smart machine damping solution, designed to eliminate chatter on the workpiece; and VSET, which simplifies component set-up by minimising the time spent on workpiece alignment and, as a result, generates set-up time savings of up to 70%.

These complement the company’s existing technologies of: ‘smart’ human-machine interface, which has been enhanced to allow — for instance — operators to view two ‘screens’ showing workpiece and machine data simultaneously on the same CNC panel (such as 3-D plans and machine condition monitoring); vertical ram balance, which is (in effect) an additional axis featuring closed-loop control and its own direct positioning system to compensate for cross beam deformation on larger portal machines; DAS+ chatter elimination; and the TBS table-balancing system for asymmetric loads.

The new factory, a short walk from Soraluce’s existing plants in Spain’s Basque Country Bergara region, cost 9 million euros and houses a 4,900m

2 assembly shopfloor served by overhead cranes with capacities up to 80 tonnes.

Machine parts are produced by a range of suppliers (for proprietary components) and Soraluce factories; the latter produce all critical machine parts, including beds and bedways, as well as the wide range of machining heads that Soraluce offers.

These heads are made in a climate-controlled manufacturing and test area (in an existing Soraluce factory) that is dedicated to head production and features the highest levels of quality control (head casings are machined in-house to ensure the necessary accuracy levels).

An indication of the thoroughness of the manufacturing process is the “exhaustive test procedure” that sees every head undergo 72hr of in-factory testing on test rigs plus 125hr of machine testing before being released.

Combined operations

A machining head that combines milling, boring, turning and grinding was demonstrated on a TA-M 25, one of a new range of Compact machines for multi-task operations on components up to 8,000mm in diameter in a single set-up.

With a chuck featuring an “innovative rotational locking system”, the bed-type machine included a grinding head that had achieved surface finishes of Ra 0.4/0.5 in trials when in-feed and traverse OD, ID and surface grinding.

Soraluce says future developments will include angular and face grinding with ‘straight’ wheels.

The new multi-tasking Compact range covers longitudinal, vertical and cross travels of 2,500 to 4,000mm, 1,250 to 1,800mm and 1,200 to 1,500mm respectively, while table capacities go up to 10,500kg (milling) and 3,000kg (turning).

Like all Soraluce machines, Compact types feature a full cast-iron construction ‘underpinned’ by finite element analysis, a high-torque direct-drive spindle motor inside the ram (with built-in cooling system), and Soraluce’s own linear guiding technology on each axis (this is based on a combination of in-house developed damping pads and INA guiding systems).

The Compact machines join an extensive range of portal machines in moving table, gantry and moving cross beam styles – all available from Soraluce’s exclusive UK and Ireland distributor, TW Ward CNC Machinery Ltd, Sheffield (

www.wardcnc.com).

These machine types cover a range of machining capacities: PM moving-table models have X, Y, Z and W (cross beam) axes from 5,600 to 7,600mm, 4,500 to 5,000mm, 1,500 to 2,000mm and 1,000 to 2,000mm respectively; while PMG, PRG and PXG gantry models have X, Y, Z and W axes of 6,000 to 10,000mm, 4,000 to 10,500mm, 1,500 to 3,000mm and 1,000 to 4,000mm.

Commenting on the new range, Ward CNC’s Stuart Lawson (head of strategic accounts and projects), said: “Soraluce’s industry-leading solutions provide Ward CNC customers with immediate access to unrivalled production technologies in terms of milling, boring, turning — and now also grinding — in a single set-up.

“This capability, partnered with our own engineering applications expertise and service back-up, means UK customers have access to cost-effective solutions to their production problems — for workpieces of every size and in all materials.”

New technologies

The display of DWS and VSET — developments driven by Soraluce’s IK4-Ideko technology centre — captured the attention of visitors to the Portal Summit.

DWS, an active damping device designed to eliminate chatter, comprises a controller and one or more ‘inertial actuators’ placed on the part to be machined.

The result is better surface finishes, especially in areas of the workpiece that may be ‘more flexible’.

DWS complements Soraluce’s DAS+ smart system for eliminating chatter, and both systems integrate with the machine’s CNC system (Siemens or Heidenhain).

Meanwhile, VSET — a measurement system to simplify component set-up — uses 3-D vision.

Two of its three modules (VSET Measuring captures optical reference points, while VSET Fitting compares measured data with a 3-D model of the part) are run with the part ‘off-machine’, without interrupting the machine operation; the third module, VSET Alignment, integrates the results of measurement with the machine’s CNC and the component positioning on the machine table.

Soraluce says VSET can pay for itself in less than a year, depending on throughput.

The IK4-Ideko technology centre has 110 full-time professionals and is dedicated to “paving the way” in manufacturing advances.

A development nearing completion is the use of “wireless inspection routines” to ascertain any volumetric errors in a machine.

The technique, which is claimed to be more cost-effective than traditional alternatives, is said to offer full calibration of small- and medium-capacity machines within 4hr.

The centre says laser interferometry will continue as the chosen calibration method for large-capacity machines.