The Innovation and Research Centre (IFC) Tuttlingen at the Hochschule Furtwangen University of Applied Sciences (HFU) in Germany and FOBA Laser Marking + Engraving (

www.fobolaser.com) have officially launched their ‘innovation

co-operation’ for medical technology.

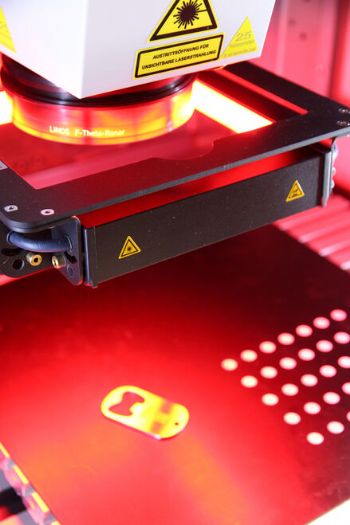

At a ceremony in March at the IFC, a modern laser marking system — an M2000-P — was presented; this is now available to the university for its research, as well as to interested parties from industry for demonstration purposes.

The combination of research and industrial application is at the heart of the work on the HFU campus; this is in the form of co-operation between the IFC and manufacturing companies, as well as for education purposes.

Innovation manager Regina Storz-Irion, who helped establish the relationship with FOBA, said: “Some 75% of our work is applied research.

“The goal of our co-operation with industry is to create benefits for the companies in the region — and put science into practice, for example, in the form of student theses.”

In order to achieve durable and high-contrast inscriptions, the laser beam must change the surface to achieve the desired marking effect, but there should be no damage to the material.

Materials scientist Griselda Guidoni is researching which laser parameters are most suitable for specific materials.

Christian Söhner from FOBA said: “Our systems already have the parameters for certain materials integrated in the software, allowing users to fall back on empirical values when setting up a marking job.

“The camera integrated in the marking system also contributes to safe and error-free marking.”