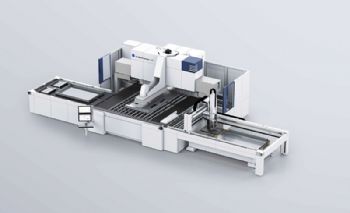

The new TruBend Center 7030 from Luton-based Trumpf Ltd (

www.trumpf.com) can bend parts up to 30% faster than its predecessor — and its tool-change times are significantly shorter.

For the first time, Trumpf has also included the option of equipping the panel bender with a loading and unloading station.

The company says that panel-bending machines such as the TruBend Center 7030 are particularly adept at forming complex parts with radius bends, short side lengths, and narrow profiles, adding that when it comes to producing parts like these, this bending technology is quicker than die-type bending machines.

To achieve the speed offered by the TruBend Center 7030, Trumpf engineers split the machine’s drive unit into two parts. Instead of equipping the machine with just one central hydraulic cylinder, the new design features one cylinder on the left and one on the right; this arrangement increases axis velocity and boosts the machine’s productivity.

Moreover, a new on-demand servo drive saves energy by only running the motor when the machine actually needs it.

With regard to automated loading and unloading, the operator can stack various piles of metal blanks on the right-hand side of the machine.

A gripper device with suction cups initiates the automated loading process by picking up a sheet — and checking that only a single sheet has been taken.

This device then deposits the sheet on a brush table, where a positioning bar ensures that it is aligned correctly.

A loading carriage moves the blank into the bending area, simultaneously removing the most recently formed part and transporting it to a conveyor belt. During this loading and unloading process, the TruBend Center 7030 continues to operate.

As well as increasing the axis speed of the TruBend Center 7030, Trumpf engineers added a feature that allows the changing of multiple small tools at the same time, reducing the machine set-up time by up to 70%.

The new machine also features the company’s TecZone Fold offline programming system, which allows bending programs to be generated “in a matter of seconds” while providing a 3-D simulation of the process — including collision monitoring.