A hot-runner and injector specialist for the mould-and-die industry that is using a range of VISI CAD/CAM software to optimise work-flow, says it is the most suitable solution for its working requirements (

www.visicadcam.com).

Sergio Pozzan, founder and owner of Injection Point SRL, said: “We use this software for feasibility studies before the production phase and to formulate quotations for customers.

“Information is better organised — and errors minimised — when moving from design to the machining phase.

“VISI Modelling is used for design, VISI Flow to simulate plastic injection flow inside the mould, and VISI Machining to program complex cycles.”

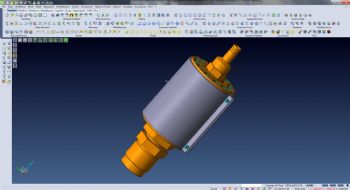

Based in Turin, Injection Point specialises in the construction of hot runners from 8mm in diameter up to 2,300mm centre-to-centre distances, along with 240V and 24V injectors and filtering systems for thermoplastics.

As well as injector lines and direct injector groups, the company also produces control units and filter nozzles.

Mr Pozzan said: “I founded Injection Point in 2001 after a considerable time in the moulding industry as a project manager, production manager and quality manager.

“I was able to make use of my experience and apply it to hot-runner design and construction, as well as to injectors for moulding thermoplastic materials.

“Now, using VISI, I can offer a widely tested product that can be used with the most up-to-date plastic materials and ensure that customers can meet all their production quality requirements.

“Thanks to VISI, our customers can count on us for everything concerning mould construction, from the design phase through to the final mould testing.

“Moreover, we guarantee one of the fastest support services in the market — within 24hr in Italy and 48hr throughout the rest of Europe.”