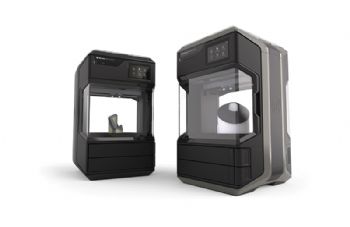

MakerBot, a global leader in 3-D printing, recently announced the launch of Method X — a manufacturing workstation engineered to use ‘real’ ABS (acrylonitrile butadiene styrene) material, a 100°C chamber and Stratasys SR-30 soluble supports to “deliver exceptional dimensional accuracy and precision for complex durable parts” (

www.makerbot.com).

Method X can print ABS that can withstand temperatures up to 15°C higher, is up to 26% more rigid and up to 12% stronger than the modified ABS formulations used on ‘standard’ desk-top 3-D printers.

Furthermore, the company says that real ABS parts printed on Method X suffer none of the warping or cracking that can occur when printing modified ABS on desk-top platforms without heated chambers.

Desktop 3-D printer manufacturers attempt to get around part deformation due to the material’s high shrinkage rate by using a heated build plate in combination with altered ABS formulations that are easier to print but compromise thermal and mechanical properties.

MakerBot CEO Nadav Goshen said: “With Method X, we are taking a step further to revolutionise manufacturing.

“It was created for engineers who need true ABS for production-ready parts that are dimensionally accurate with no geometric restrictions.”