Industrial finishing equipment manufacturer Guyson International Ltd, Skipton (

www.guyson.co.uk), has focused its expertise on solving a problem encountered during the production of orthopaedic implants by additive manufacturing.

The company’s new Powder Flush has been designed specifically to flush residual additive-manufacturing (AM) powders from medical-implant trabecular structures, which help the interlocking human bone to grow into the implant.

Additive manufactured orthopaedic implants are typically made by SLS (selective laser sintering), SLM (selective laser melting) or EBM (electron beam melting) from titanium powders in the size range 5-45µm for the SLS and SLM processes and 45-90µm for EBM.

After manufacture, the implants have the bulk of the residue powder removed from the build block with brushes and by vacuum, sometimes followed with an air-wash or blast process to remove any semi-adhered powder particles, but because of the nature of the porous trabecular structures, some powder is often still trapped inside the component, and this must be removed.

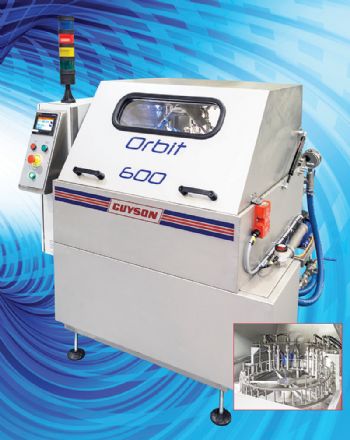

Guyson’s Powder Flush is based on its Orbit 600 rotary basket spray wash unit, fitted with a 100-litre insulated tank and hot-spray flushing.

The machine offers directed jets for powerful component flushing, followed by a compressed-air ‘wash’.

A PLC/HMI control panel to the left of the machine provides data monitoring and a timed pre-heat function to ensure accurate and repeatable processing.

In operation, the implants are loaded individually or in batches on non-contaminating fixtures; these present the workpieces to the directed flushing jets in close proximity to the trabecular surface, thus ensuring thorough powder removal.

Timed electronic door interlocks prevent the door opening during operation and until the hot steam has dissipated at the end of the process time.

Guyson’s managing director, Mark Viner, said: “This new Powder Flush unit adds to the already extensive portfolio of Guyson products provided for the 3-D printing/additive-manufacturing market.

“These include our Euroblast Ex range of ATEX-certified blast cabinets for surface-finishing exotic metal AM parts, often used in the aerospace and medical markets.

"The Guyson PRS (powder recovery system) for EBM additive builds uses robotic blasting methodology to reveal components and manage the resultant powder, while our Kerry range of ultrasonic baths and tanks is for the removal of 3-D printed fused deposition models.”