The Whitchurch-based (Hampshire) tool maker and plastic injection moulding specialist BM Injection Ltd has, over the years, replaced the time-consuming electric-discharge machining (EDM) of moulds and dies with direct milling of the tool steels in their hardened state — up to 58HRC in the case of 2083,which is used for the injection moulding of highly abrasive thermoset plastics.

Until recently, hard milling was undertaken on a three-axis vertical-spindle machining centre (VMC), while the only five-axis model on site was reserved for light mould finishing and machining complex (mostly graphite) electrodes for ‘sparking’ cavities.

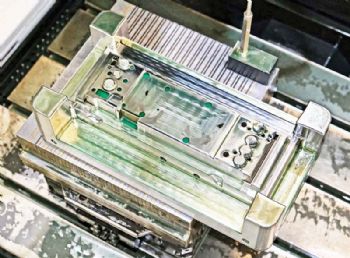

A few months ago, BM Injection bought a second five-axis VMC — a Japanese-built Makino D200Z.

Supplied by Thames Ditton-based UK agent NCMT Ltd (

www.ncmt.co.uk), this is used for the rough and finish milling of tool steels to single-figure micron accuracy.

Moreover, machining is now carried out ‘in one hit’, including complete milling of the ‘gate’. Previously, at least two operations were needed — three if a route involving milling plus electrode production and EDM was chosen.

Consequently fewer skilled operators are now needed, cutting production costs and alleviating the problem of recruiting experienced staff.

Machining in one clamping by automatically repositioning the workpiece in-cycle using the two rotary axes results in higher accuracy by eliminating tolerance build-up; and because the Makino has internal sensors and cooling of the spindle, ballscrews and machine structure, extremely high levels of precision can be held — even though BM Injection’s factory is not temperature-controlled.

Directors Tim Combes and his son Mark refer to a 54HRC Stavax test piece machined by Makino under controlled conditions in its test laboratory in Japan to a 2µm total tolerance, saying that tolerances just double that are achievable on their shopfloor.

Tim Combes said: “Dimensional accuracy is critical when producing moulds and dies.

“We need to hold ±0.012mm on cavity dimensions, interpolated diameters and hole positions.

“Surface finish is also important. A mould that takes 20hr to hand-polish if it is produced on a sparker can — after direct milling on the Makino — be finished in 3-4hr, which is an enormous saving.

“Moreover, lead times from order to completion have been cut by an average of 40%.”

Mark Combes added: “In the case of side-action mould tools, we previously needed to grind them prior to die sinking to achieve the required finish.

“Now, nothing needs grinding, and the moulds are finished in one set-up on the D200Z.

“Also, as the machine’s high volumetric accuracy leads to less hand-polishing of cavities, it is easier to hold the true shape of the mould and die, because less material is being removed.

“This is especially important when making tools for the production of lenses and other optical parts.”

Apart from the Makino’s ability to hold very high accuracy over its entire 350 x 300 x 250mm working volume, another reason for its selection was the small footprint (about 2.75 x 3.75m).

This is important, as space is limited in the Whitchurch facility. Other features of the machine include a B axis with 180deg of tilt (at 100rev/min), a 150rev/min C axis (table), a 30,000rev/min HSK-E50 spindle, and cutting feed rates up to 60m/min.

A place for EDM

Despite the increasing prevalence of hard milling, the Combes say that there will always be a place in tool-making for EDM, and both die-sink and wire erosion machines are in use at Whitchurch.

To take advantage of the latest technology in this area, BM Injection added a second spark erosion machine, ordering a Makino EDAF3 with the HEAT option (high energy applied technology); this was installed at the same time as the new five-axis machining centre.

Tim Combes said: “It is a stunning die-sinker that is compact and totally reliable, even on demanding jobs, and it can machine to accuracies measured in low single-figure microns.

“It raises the interest of shopfloor staff — and it impresses our customers when they visit.

“The level of intelligence built into the machine means that one tool maker can operate both die-sink machines and the Makino.

“Deep ribs can be produced quickly and reliably — and with low wear on the graphite electrodes.

“Constant attendance at the EDAF3 for manual intervention to avoid the onset of arcing — for example — is not required, due to the effective spark gap monitoring and arc-prevention circuitry.

“Makino’s HEAT option, which incorporates dual high-pressure digitally controlled flush pumps and a large-capacity four-step filtration system, provides even faster machining speeds and higher levels of accuracy — even under poor or difficult flushing conditions.”

The latest EDAF3 has a new flushing control and feed rates up to 5,000mm/min in the X and Y axes.

Another feature, HS-Rib, gives the Z axis a ‘jump speed’ of 20m/min — a 31% increase over the previous model.

Ease of operation is provided by a Windows-based CNC with a touch-screen, allowing complex parts to be programmed, even when the control is being used by less-experienced staff.