HP has expanded its relationship with Oakley, helping the latter to advance the brand’s ‘sports performance design process’ to meet the needs of athletes.

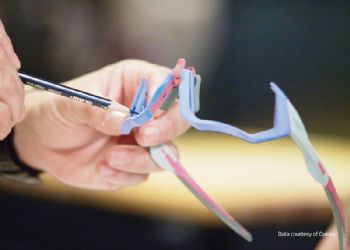

With HP’s Jet Fusion 3-D printer (www8.hp.com), Oakley is re-inventing how the company prototypes and creates functional parts by ‘leveraging the technology across its portfolio of sports accessories, equipment and lifestyle products’.

Nicolas Garfias, head of design at Oakley (

www.oakley.com), said: “World-class athletes around the globe depend on Oakley to compete at the highest level.

"With HP’s breakthrough 3-D printing technology, we will not only accelerate our design-to-production timeline but also re-conceptualise the way our products are made, pushing the boundaries of sports performance to new heights.”

Oakley has been prominent in the sports industry for over 40 years, and “at the forefront of how performance products and technologies are developed and produced”.

In 1992, the company began integrating 3-D printing into its design process, which transformed its development process “and the silhouette of our sunglasses”.

Knowing the value of 3-D printing, Oakley has — since 2018 — been leveraging HP technology for rapid prototyping across multiple product lines, including :

great pairs of sunglasses, helmets and more.

Jeff Fawcett, part of the 3-D printing product management team at HP Inc, said: “Oakley has the highest of design standards, and our innovative 3-D printing technology helps the company deliver on that experience for millions of athletes around the world.

"Together, we are transforming the sports performance community and changing the way the world designs and manufactures consumer products.”

Oakley is demonstrating the power of digital manufacturing, using HP’s Jet Fusion 580 platform to take a 2-D sketch off the page and make a design model a reality, including the ability to: speed up the design iteration process (Oakley designers can now see parts and conduct tests in just 24hr); benefit from the use of colour; test functional parts; and create small and large prototypes in one build session.