ModuleWorks, Bosch Rexroth and CIMT have combined their technologies to bring real-time machining simulation to digital dentistry. ModuleWorks real-time simulation runs directly on high-end CNCs and provides accurate 3-D visualisation of the machining process including material and machine simulation.

Bosch Rexroth (

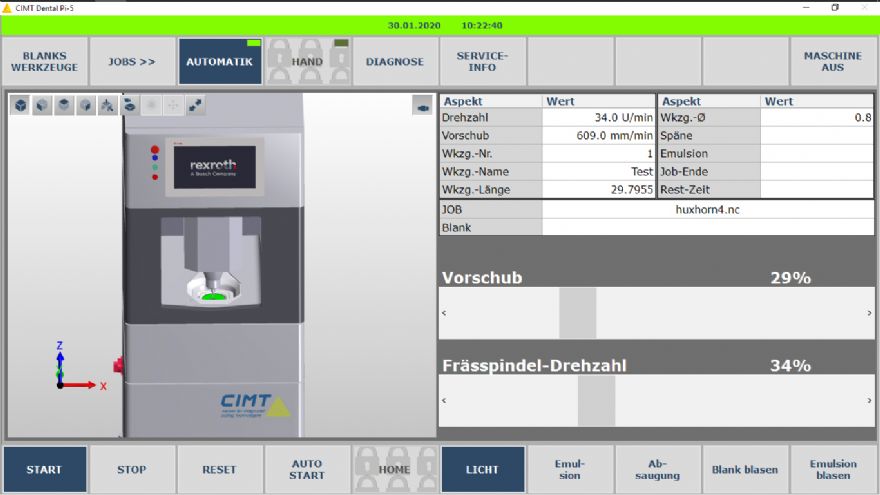

www.boschrexroth.com) has integrated this functionality into its MTX CNC that enables operators to view the simulation either directly on the CNC’s touchscreen HMI (human-machine interface) or on a remote device such as a laptop.

CIMT, a Germany-based specialist for integrated milling technology, saw the potential of this technology for digital dentistry and is now using the Bosch Rexroth MTX with integrated ModuleWorks (

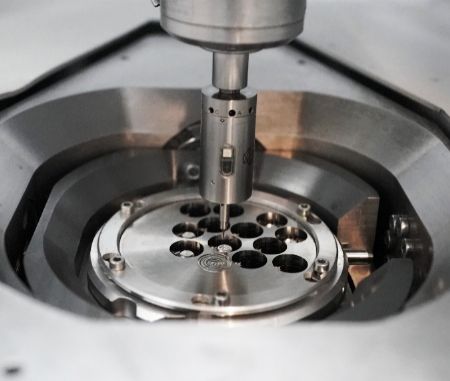

www.moduleworks.com) simulation for its high-performance Tizian 5.4 dental milling machine.

Christian Heine, CEO of CIMT, said: “Real-time simulation is already the standard in many machining applications, but until now it was not being used in digital dentistry.

“We saw a great chance to change this. The ModuleWorks simulation software is directly integrated in the Bosch Rexroth HMI which enabled us to quickly and efficiently build it into our dental milling solution.”

Soroosh Eghbali, head of CAM automation and digital dentistry at ModuleWorks, said: “It is great to see how CIMT is using the simulation technology from our industrial portfolio to add value to digital dentistry.

“This brings us closer to our vision of providing the most advanced manufacturing technology to the digital dentistry market and creating more-efficient workflows that optimize the profitability of dental labs and practices.”

Tightly integrated in the MTX, the ModuleWorks simulation technology has direct access to the real axis positions, machine geometries and workpiece position and uses the same motion data as the real servos to deliver a highly accurate real-time simulation of the entire machine kinematics.

CIMT operators benefit from a detailed and unobscured visualisation of the whole dental machining process from every angle in real-time. The simulation also offers visual aids such as a deviation analysis to highlight the rest material after machining.

Dr Karsten Kreusch, product manager CNC and motion control systems at Bosch Rexroth, said: “Because the ModuleWorks simulation technology is integrated in our MTX CNC, all the machine parameters and data are included in the simulation and you can easily catch potential problems that you cannot see during a CAM simulation.”

Used in combination with the Bosch Rexroth digital twin, the ModuleWorks technology also enables CIMT operators to simulate the dental machining process offline on a virtual machine to quickly identify and fix any problems before starting the real machining job.

This reduces machine downtime, keeps production moving and ensures cost-effective use of material in dental labs and practices.

Mark Foti, head of digital factory at ModuleWorks: "It is exciting to see how shopfloor technology developed by ModuleWorks is being leveraged and used across multiple industries. Our goal is to develop versatile technology that can be integrated and used in many different ways to help our partners, regardless of which business area they are in."