In what is one of its largest single orders to date,

Stratasys, has announced that Latvia-based

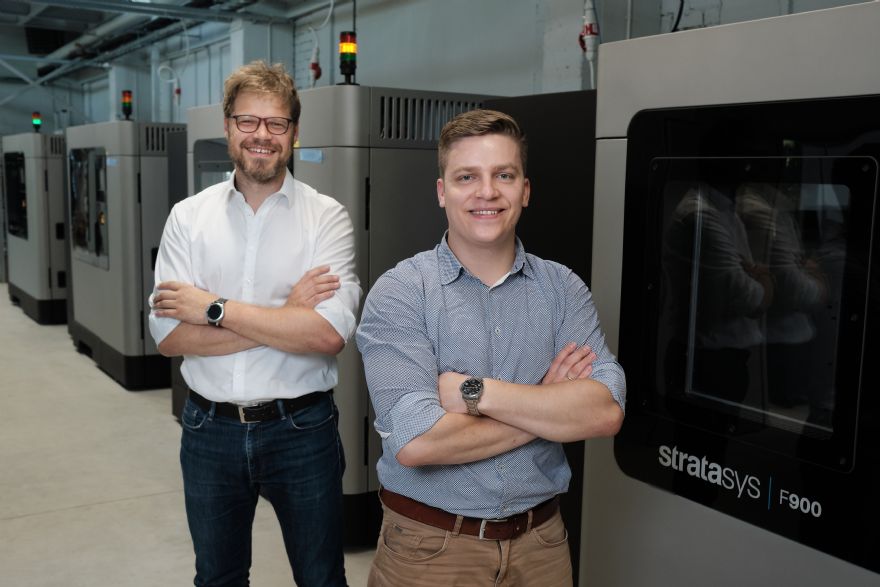

AM Craft, a specialist aerospace additive manufacturing (AM) service provider, has purchased four large-scale production-grade Stratasys F900 3-D printers to produce certifiable 3-D printed parts for a wide range of aircraft interior applications.

This includes everything from aircraft seating, panelling and ducting, as well as making it more affordable for its aerospace customers to introduce customisation within the cabin.

Jānis Jātnieks, AM Craft co-founder and CEO, said: “In recent years, we have seen an ongoing demand for 3-D printed parts among major aircraft OEMs.

“Although Covid-19 has shocked the industry in the last few months, we are seeing efforts to return to business by remodeling passenger planes for cargo shipments, as well as projects to increase customer safety measures and improve the in-flight customer experience – for example by providing mobile device charging stations and wi-fi infrastructures.

“In such cases, AM is way ahead of slower and more costly traditional manufacturing methods.

He added: “One of the mainstay pillars that enables us to realise this business case into real-world applications is Stratasys’ highly-repeatable FDM-based 3-D printing technology in conjunction with aerospace-grade materials like Ultem 9085 resin.

“Crucially, this gives us the capability to meet strict rules and regulations around certification that require the highest level of repeatability and traceability with every part manufactured.”

The flame-retardant, high-performance Ultem 9085 resin meets stringent flame, smoke and toxicity (FST) criteria and retains traceability required by the aerospace industry.

The material is used by aircraft manufacturers such as Airbus, which has successfully standardised it for the production of thousands of flight parts for its A350 XWB aircraft.

Lightweight aircraft interior partsCertified to Airbus material specifications, Ultem 9085 resin allows the company to produce strong yet lightweight aircraft interior parts at significantly reduced manufacturing cost.

AM Craft’s investment will compliment an existing hardware line-up of four Stratasys Fortus F450mc 3-D printers.

Collectively, the battery of eight FDM-based machines will provide the heartbeat of a dedicated new AM facility in Riga that will focus specifically on fulfilling the application requirements of the company’s customer base of aircraft suppliers and airlines.

Yann Rageul, Stratasys director of manufacturing solutions, said: “As the Covid-19 pandemic caused the world to re-think supply chain strategies, AM Craft was already a step ahead.

“The same flexibility offered by Stratasys FDM technology that allowed aerospace manufacturers to change gears and quickly produce personal protective equipment in response to supply chain shortages, is what can enable those same aerospace companies to advance their goals in cabin customisation.

Both recovery from supply chain disruptions and cabin customisation require repeatable, cost-effective, low volume manufacturing, and that is exactly what AM Craft has invested in with Stratasys.”

AM Craft’s investment will see the company become one of the largest independent aerospace-focused 3-D printing service providers in the EMEA (Europe, the Middle East and Africa) region.

The business will operate as a sister company to Baltic3D, an established 3-D printing service provider that has worked closely with companies within the aerospace supply chain since 2017.

AM Craft’s Riga facility is expected to be fully operational by the end of 2020.