The range of machine tools from the

Chiron Group has now become even smarter with the new ProtectLine and CutLine software solutions that have been introduced to enhance digital production. Available in the UK & Ireland from the

Engineering Technology Group (ETG), the new modules form part of the SmartLine portfolio with which the Chiron Group has assumed a leading position in the market.

The digital products are perfectly harmonised to add value to the company’s extensive range of machining centres, making it possible to increase productivity, improve part quality and boost machine availability and capacity.

The new software developments from Chrion sit comfortably within the ETG portfolio, with the Wellesbourne company already offering an extensive range of Industry 4.0 digital manufacturing solutions to its customers.

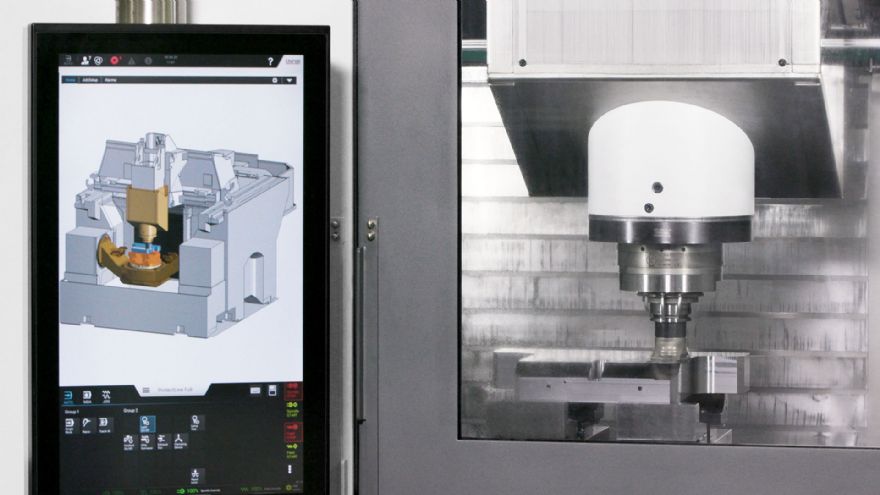

The ProtectLine software solution allows companies to reliably prevent potentially significant, expensive damage and production downtimes. The system is characterised by a digital twin that runs ahead of the physical machine in ‘real-time’ during the operational mode.

This means that if the digital twin encounters problems or even a crash, the software shuts down the machine in a controlled manner that preventatively protects it from collisions – protecting the investment and gives peace of mind.

One of the main features that sets this software solution apart from other established systems is that the simulated model always corresponds to the real current production situation. Machine crashes can be reliably prevented, even in the case of small adjustments or operating errors.

By doing this, the solution contributes to a significant improvement in productivity. A further advantage is that ProtectLine is integrated directly into the new TouchLine control panel. This makes operation very simple, which is a credit to its intuitive and context-sensitive operating concept.

Meanwhile, ProtectLine fully replicates the physical machine and this includes the complete machine tool, cutting tools and tool holders, as well as the workpiece with the respective clamping arrangement that can all be part of the model.

Just like a ‘real’ machine, the software enables virtual tool changes and simulates a virtual machining process in parallel to the real machining process.

Through this unique simulation, the geometry of the virtual workpiece always corresponds to that of the real workpiece, resulting in a very realistic model.

Used together, the ProcessLine and ProtectLine modules of the SmartLine portfolio form an integrated digital process chain. Whereas ProcessLine simulates the real NC program in a preparatory stage, ProtectLine provides reliable protection against the consequences of operating errors in the ongoing operation.