Hersham-based

Fimark Ltd, a laser engraving, cutting, marking and texturing sub-contract specialist, has invested in a ‘state of the art’ AgieCharmilles Laser P 400U laser texturing machine supplied by Coventry-based

GF Machining Solutions.

The machine was installed at the company’s facility in July 2020 and is the second AgieCharmilles advanced, high-performance five-axis laser texturing machine that Fimark has acquired in the last five years; the first being a Laser 1000 5AX machine that was installed in April 2015.

The latest arrival has not only significantly strengthened the company’s existing laser marking, engraving and etching capabilities, but has also enabled Fimark to further develop and exploit new application opportunities in the relatively new, and emerging, laser 3-D texturing markets.

Fimark’s managing director Charles Dean said: “Laser texturing is a fully digitalised surface engineering process that has huge potential. The technology enables precise 2-D and 3-D textures to be machined accurately and directly onto complex parts or moulds/mould inserts, and its application is being investigated, trialled and used by manufacturers world-wide, serving a wide range of industry sectors including automotive, aerospace, medical devices, watch making and jewellery.

“We are an innovative company and our ‘early adoption’ of laser texturing technology, achieved through the acquisition of the Laser 1000 5AX and, more recently by our latest Laser P 400U investment, reflects and reinforces our ambition to become and remain a market-leader in this fast-growing specialism.”

Fimark was established in 1997, and in the early days the company was primarily focused on providing high-quality laser engraving and marking services to customers.

Laser machining technology specialistIn 2002 Fimark enhanced its original service offering by employing its technical spray painting and laser etching expertise to manufacture back-lit buttons and fascias (used in dashboards and cockpits etc), for its aerospace and automotive customers.

Through constant investment and improvement in its plant and equipment, and in its systems and processes, Fimark has established itself as a ‘go-to’ laser machining technology specialist. The company’s impressive domestic and international list of customers is testament to this.

The decision by Fimark to invest in the Laser P 400U machine was reached in late 2019 following a surge in demand for its high-quality laser machining services which was putting pressure on the company’s existing laser resources.

Mr Dean continued: “It was clear that we needed to increase our laser machining capacity and capabilities. Certain jobs, like the laser texturing of mould tools, involve long processing times and were tying up our existing machining resources.

“Furthermore, it was also clear that many machining jobs we were undertaking could be completed on a smaller five-axis machine.

“As we had experienced no problems with the Laser 1000 5AX purchased in 2015 we approached GF Machining Solutions to discuss our future requirements. Through this process we made the decision to invest in a new Laser P 400U machine.”

Compact and versatile five-axis machineThe new machine is a proven, compact and versatile five-axis machine that can accommodate workpieces up to 600 x 400 x 250mm. It features a dual laser head that can incorporate both an ytterbium pulsed (nanosecond) fibre laser and an ultra-short femtosecond pulsed laser.

The dual head arrangement allows a multitude of different laser operations to be undertaken on the one machine including texturing, marking and engraving, and significantly increases the range of materials that can be processed.

The Laser P 400U, with its 30µm laser beam width, is ideal for machining small components with delicate and intricate shapes, features and textures. For ease of set-up and process control, the machine’s head features a sophisticated vision system camera and a 3-D touch probe.

Since its installation the Laser P 400U has been used for a range of engraving, etching and texturing jobs as well as in a number of research-led and production-led applications that include the surface modification/manipulation of stainless steel to develop hydrophobic and hydrophilic properties, and the high-accuracy laser etching of chip breakers onto PCD cutting tools.

A significant (yet largely untapped) growth area for Fimark, facilitated by its investment in the two laser texturing machines from GF Machining Solutions, is in the laser machining of 3-D functional textures which have many purposes and can be applied to parts and components in order to alter and/or improve their functionality and performance.

Specific textures can be created, for example, to enhance/improve the tribological properties of surfaces to improve their load bearing capacities or to reduce friction and wear.

In addition to ‘functional’ textures, surface texturing can also be used to enhance the look and feel of numerous components and parts.

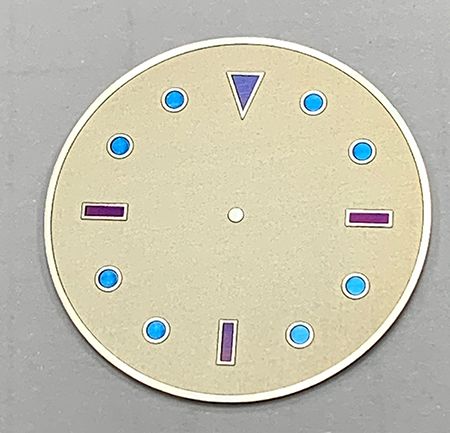

Typical examples of this include special editions and customised versions of ‘luxury’ goods (including jewellery, watches and cars), with laser texturing technology providing a real cost-effective alternative to more traditional methods such as engraving and chemical etching. Pictured left is a watch dial with laser coloured batons produced on the Laser P 400U.

Mr Dean concluded: “In many aesthetic and functional applications laser texturing has a number of clear advantages over more conventional surface etching processes — it is less harmful to the environment, less labour intensive and moreover is a more reliable and repeatable process.

“This is where the future of laser machining lies and, with our latest investment, we are making sure that we are positioned at the forefront of any developments.”