Axsys Industries

Axsys Industries, a young French industrial group specialising in machining and boilermaking, made the choice to go "digital" at an early stage, to improve efficiency and productivity. In particular, the company, based at Le Plessis-Pâté, France, relies on the full “digital twin” in NCSIMUL’s G-code machining simulation and verification program along with Workplan production control software.

Reaching the age of 40 can be a turning point in many people’s lives and it was certainly the case for Franck Bonassera ten years ago. A manager with an eclectic background, he decided to embark on an entrepreneurial adventure, taking the reins of ARM, a company specialising in precision machining.

His initial aim was to increase turnover fourfold in ten years. Nine years later he acquired CSI, a business strong in boilermaking, locksmithing and mechanised welding, and quickly transformed operations.

Mr Bonassera's managerial talents in seeking new customers, investing in new machines, diversifying, and obtaining ISO 9001 certification, along with his intuition in the benefits of industrial computing, all contributed heavily towards this success.

Aware of his shortcomings in mechanics, he decided early on to train as a machine-tool setter, passing a certificate of equal qualification in metallurgy. He said: “I am as proud of this diploma, as I am of my MBA obtained at the Neoma Business School.”

Mr Bonassera’s intuition was confirmed during that training course. He explained: "Until then, we had been manufacturing in a conventional way in our workshops. It was absolutely necessary to move to the digital stage, in order to finely control our production times, eliminate machine incidents as much as possible, and improve quality — while making it easier to produce quotes and invoices."

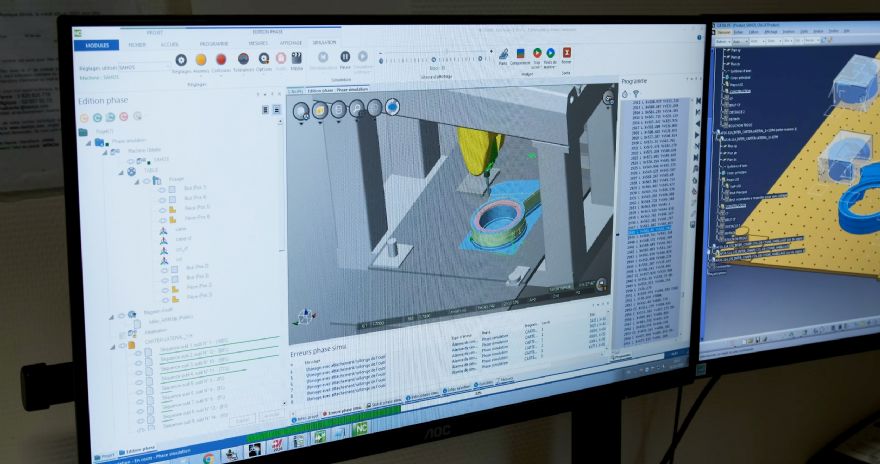

To create a digital chain from customer order to final manufacture, the ARM specialist machining division invested in Workplan production management software and the NCSIMUL simulation solution – both supplied by the

Hexagon group.

He continued: “I wanted production management that delivered time and cost indicators, and readily showed which manufacturing orders we saved or lost time on, and which quotations were saving or losing us money. Workplan’s monthly profit and loss account is ideal for showing us this at a glance. It also offers the possibility of scheduling tasks, optimising machine usage time.”

His extensive experience had taught him that standard machining toolpath programming can contain two types of errors; those related to human programming and those related to the post-processor.

“NCSIMUL automatically eliminates these errors from the post-processor and programmers, thanks to the performance of the digital twin which verifies the programs by simulating the actual machine G-Code."

But his interest in NCSIMUL does not stop there, as its programs feed a database that can be used by all operators. This means the company retains details of all practical cases, whereas in the past, whole areas of know-how were lost when, for example, a senior employee retired.

Mr Bonnassera concluded: Eventually, the ARM teams intend to make full use of the potential of Workplan and NCSIMUL. The two software packages are opening the doors to automation for us, and the use of our production tools 24hr a day

“The Hexagon Group has been a reliable partner during this expansion of skills, in particular through supporting ARM staff in the digitalisation process. This is a very nice demonstration of the impact of a software suite on the productivity of the workshop — an example to be followed.”