If you topped up the fuel in your car this week you might want to thank Conroe Machine, because this job shop in Conroe, Texas, machines most of the components used to build downhole Positive Displacement Motors (PDMs).

Known in the oil and gas industry as ‘mud motors’, they are commonly used for directional drilling of oil and gas wells; and without them, the oils and fuels needed to power our vehicles and heat our homes would ‘stay forever underground’.

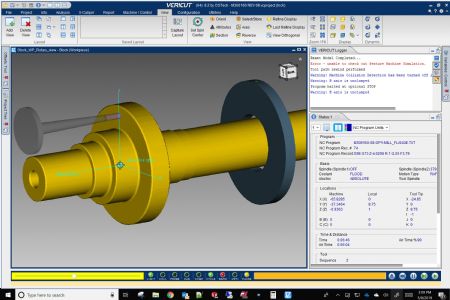

James Wardell is the the programming technology manager at Conroe Machine and part of the team that implemented Vericut tool-path simulation software from CGTech (

www.cgtech.co.uk).

He said that without this software, the company’s machining operations would be less efficient, less safe, and much less predictable.

“Machining has grown more complex over the years. It is no longer just linear moves and simple arcs, but also dynamic roughing paths and 3-D surfacing, as well as simultaneous four- and five-axis cutting.

“You can’t expect a machinist to catch program errors in this situation, which is why we needed a system that can verify our NC programs and give us confidence in advance that everything is good to go.”

Mr Wardell points out the fact that Conroe Machine produces much more than mud motors. Since 2000, this 160-employee 65,000ft

2 facility in Conroe’s North Industrial Park has machined a wide array of high-precision parts for companies that include Halliburton, National Oilwell Varco and Global Drilling Support International.

These parts include sub-sea components such as ‘stab plates’ and various control valves, many made from Inconel, Nitronic 50, ToughMet and other ‘challenging’ materials. The company also has extensive fabricating and engineering capabilities.

“We make bearing races, housings and PDM transmission parts by the hundreds of thousands; we also do a lot of low-volume and prototype work. Much of what we do here centres around the oil and gas industry, although after the last downturn we have tried hard to diversify our customer base, and have expanded our service offering accordingly.”

Five-face machiningPart of that expansion was the purchase of a Toyoda SB316YM, a fixed rail bridge-style five-face machining centre with a 22,000-pound table capacity and 118in of X-axis travel. Mr Wardell and others there call it the company’s flagship machine; and it was just prior to installing this Toyoda that Conroe Machine switched its programming system to Mastercam and invested in the Vericut software.

Mr Wardell says Conroe Machine had plenty of other reasons to purchase Vericut, as the company has an ‘impressive array’ of CNC machine tools, including an Okuma LU45 II four-axis lathe, Doosan DMV 5025 and 3016 machining centres, a 120in Mighty Viper 3100 vertical milling centre — and more.

However, it was the ‘tremendous crash potential’ that comes with five-sided machining that helped convince the management team of the necessity for accurate tool-path simulation.

“We also have several automated production cells, with inline inspection and robotic part handling, but it was the bridge mill in particular that got us thinking about Vericut.

“We wanted a way to verify that the post-processors on our new CAM system were accurate, and that we could catch any programming errors before they got to the production floor, possibly damaging the most expensive piece of equipment in our shop.”

That was five years ago, and Mr Wardell says Vericut continues to prove its value every day. “We have not had any crashes due to programming error since implementing Vericut.

We have had a couple missed dimensions here and there — stuff that I might have ‘fat-fingered’ or forgotten during programming, but that is why I started using the Auto-Diff function in Vericut, to make sure everything is where it is supposed to be and that I didn’t miss anything.”

Shorter set-up timesMr Wardell also said that aside from crash avoidance, Vericut also reduces set-up times. “Because the operators can see the entire program in advance, there is less guesswork and less apprehension.

“Machine setting simply takes a lot longer on an unverified program, as the operator has to meticulously dry run each line, with hands on the override and feed hold the entire time. With a

Vericut program, they can just go for it.”

In fact, Mr Wardell says machinists at Conroe no longer trust programs that have not first been run through Vericut. This is a rare occurrence in his department, though, and about the only time he doesn’t simulate an entire program is when using a specially shaped cutter or unconventional work-holding and has not had time to model it in his CAM system.

“For those thinking about Vericut but concerned over the amount of work-holding and tool-holder modelling necessary to exactly replicate the machining environment, don’t be.”

He explains that he will sometimes draw a rough outline around non-standard tooling, “just enough to detect a collision,” and says he never did model the entire machine tool, “only those areas where interference with a tool-holder or fixture is a distinct possibility.

“If there’s any way I can use Vericut I will, and the operators feel the same way. If they have had to edit the program, for example, they will ask me to simulate it again, just to be sure they did not miss a decimal point or a minus sign.

“We pride ourselves on being a ‘cutting-edge’ shop, and are always looking for technology to make our shop more efficient, safer, and better equipped to maintain our high-quality levels. Vericut definitely helps us achieve that.”