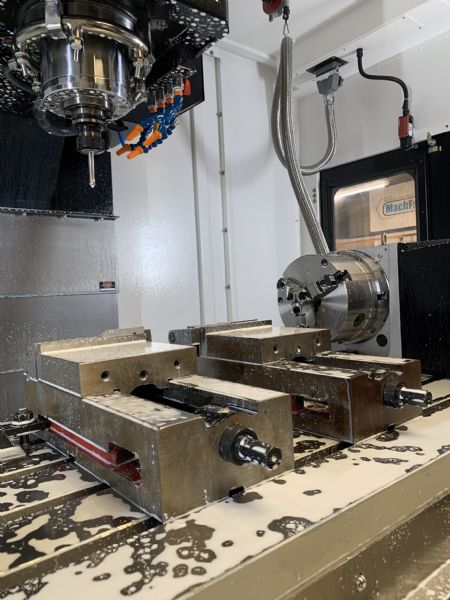

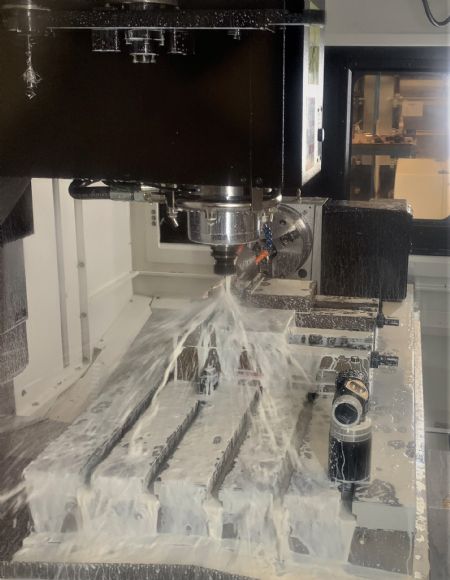

The Dugard 1100 in operation at Machfab Engineering

Despite only being founded in 2004, Birkenhead-based

Machfab Engineering Ltd is managed by directors with more than 60 years’ of manufacturing expertise in all aspects of machining, sheet metal and fabrication. But regardless of experience, we can all learn new tricks – and for this company, the learning curve has taken a new twist with investment in 3-D printing and also CNC machine tools supplied by East Sussex-based machine tools supplier

Dugard.

With customers in industry sectors including automotive, aerospace and off-shore through to the petrochemical, pharmaceutical and food industries, Machfab offers a complete range of services that ranges from conventional and CNC milling and turning, jigs and fixtures, breakdown and repair work, press tool manufacture, reverse engineering, prototyping, R&D as well as sheet metal-working. Some of these services were not previously available.

Ian Hazlehurst, Machfab Engineering director, said: “Two years ago, we had the idea to diversify the company, we have always predominantly been a conventional machine shop and we wanted to get into CNC machining -— but we wanted to do something different to everybody else. So, we made the decision to go down the additive manufacturing route. Through the Liverpool Innovation Fund we managed to get financial support to purchase our first 3-D printer.”

“We bought a Stratasys 380mc to primarily get into prototyping for R&D work. If we can get a project where we get a final part, we would never be able to offer the service to manufacture that part. So, this is why we invested in CNC machining to offer customers the full package.”

Another reason the company opted to invest in CNC machine tools was that it was not always competitive on batch work or small production runs of components. Mr Hazelhurst explained: “We weren’t competitive on volume work as everyone has CNC machines and we had conventional machines, which meant our production times were a lot longer. So, we decided as part of the project with the 3-D printer to invest in two Dugard machining centres.”

The sub-contract manufacturer simultaneously purchased a three-axis Dugard 1100 machining centre with a rotary table as well as a Dugard 1000E machining centre. He added: “The story behind the Dugard 1000E machine is that Dugard actually gave us the machine as a ‘test machine’ as we had initially decided to buy the larger Dugard 1100. The Dugard 1000E machine was installed for our guys to learn on - as it has similar characteristics — and we liked the machine so much, we bought it as well as the larger Dugard 1100.”

For a company that had not yet stepped into the realms of CNC machining and had a history steeped in conventional machining, the initial loan of the CNC machining centre to prepare the North West Company for CNC production goes a long way to demonstrate the service provided by Dugard.

Mr Hazelhurst said: “We wanted a machine that gave us the diversity of components that we could put on the machine. We have a 4th axis unit installed on the machine, so we can offer additional services and flexibility. We also have a Renishaw probing system which means that we can take measurements of parts before we remove them from the machine - as certain customers asked if we could do that. Equally important is the fact that the machine has a large bed and a powerful spindle where we can take large chunks of material off, and we can machine hard steels as well.”

The Dugard 1100 VMC provides X, Y and Z axis travels of 1,100 x 610 x 560mm with a 1,000kg maximum table load that can be accommodated on the 1,250 x 600mm bed. The machine also provides a 20 to 10,000rev/min speed range that guarantees exceptional levels of torque.

Complementing this is the 24-position automatic tool change carousel and the BT40 spindle taper that permits heavy duty cutting on a complete range of materials, including the most challenging aerospace-grade materials. Furthermore, both machines supplied to Machfab feature a Siemens CNC control.

However, the machine is also available with Fanuc or Mitsubishi CNC options to suit the requirements of the end-user.

Mr Hazelhurst concluded: “Now we have the Dugard machines, we know we can make the parts and we know we can make them right. The machines also make us competitive, so we pride ourselves on the fact that we know our pricing will also be right and we will deliver on time — we can guarantee that customers will always get exactly what they ask for.”