Engineering firm

www.forth.uk.com Forth, which is working on the development of an innovative autonomous underwater survey robot — Autonomous Aquatic Inspection and Intervention (A2I2) — that could save industries across the world hundreds of millions of pounds each year, is now looking for partners to bring the working prototype of the product to the commercial stage, following successful trials.

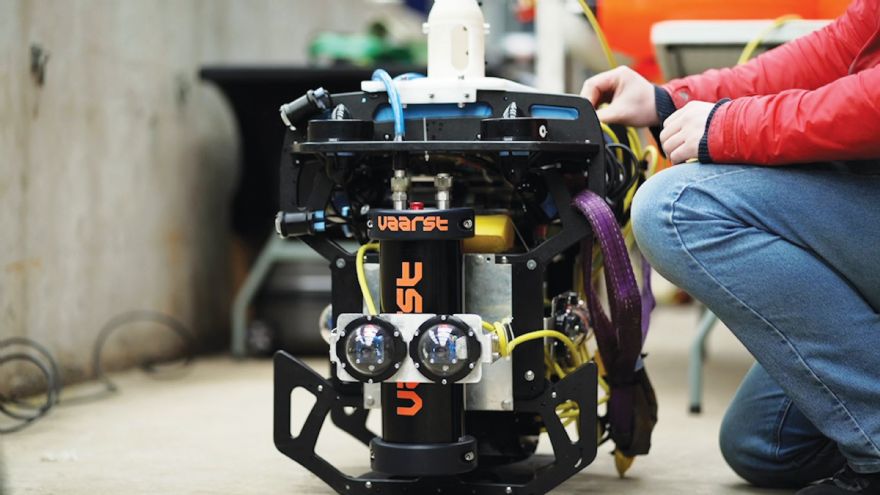

A2I2, which was developed by a collaboration of companies from throughout the UK, is an intelligent, tetherless robot that is fitted with sonar technology to detect and avoid obstacles underwater; it can be operated in hazardous environments, such as in storage ponds on nuclear sites, from a safe, remote distance.

It is estimated that the robot, which has been successfully tested during two trials at Forth’s Deep Recovery Facility in Cumbria, will save the UK sub-sea industry alone £75million, and will also significantly benefit the nuclear and oil and gas industries.

During recent trials at Forth’s wet test facility — one of the largest of its kind in the UK — the A2I2 successfully moved autonomously through the pond, avoided collisions, located items on the pond floor and relayed images that were able to be viewed, analysed and interpreted in real-time on screens nearby on dry land.

Chris Downham, Forth’s programme manager, said: “A lot of hard work and endless amount of hours has gone into producing a working prototype of such an intelligent and pioneering piece of technology, and we are proud of the success of the trials. We have witnessed first hand what a groundbreaking piece of technology it is.

A2I2 is built to withstand even the most hazardous environments, and this development will improve the health and safety for underwater work, with the machine being operated remotely from a safe distance.

“A really exciting opportunity has become available to jump on board and work to bring this outstanding piece of machinery to the market, and we would love to hear from those who want to support the project and bring it to a wider audience.”