CAD/CAM software developer

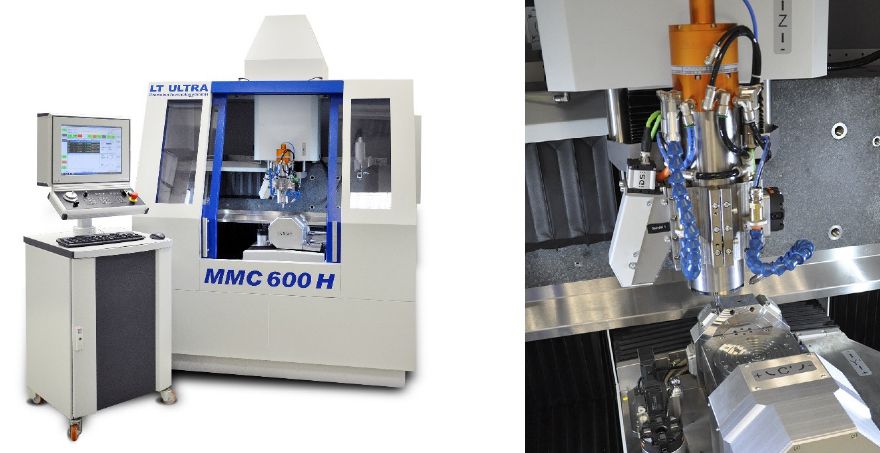

ModuleWorks and Germany-based

LT Ultra-Precision Technology GmbH, an ultra-precision technology specialist, have collaborated on a software solution for milling and turning. Built upon the ModuleWorks’ six-axis optics kernel, the new software enhances LT Ultra’s machining platforms with automated workflows for manufacturing diverse parts with nanometer (nm) precision.

The ModuleWorks optics kernel has been developed to meet the growing demand for machining increasingly complex free-form geometries with a precision in the nm range. Integrated into the LT CAM product line, it enables LT Ultra to offer flexible solutions for a wide range of ultra-precision machining applications with automatic toolpath calculation from point clouds, CAD models and analytical functions as well as corrections based on real-measurement data.

The calculated toolpaths are automatically available for full 3-D machining simulation and output via a high-performance CNC posting framework that uses multi-threading for fast generation of large NC programs (up to 50,000 points per sec).

Dr Kurt Haskic, head of research at LT Ultra, said: ”The ModuleWorks optics kernel allows the full potential of machines to be exploited. The exceptional calculation precision in the nm range and flexible adaptation to our series and custom machines are outstanding. For our customers as well as our own contract manufacturing, we have developed a solution in close cooperation with ModuleWorks that prepares us for the future of ultra-precision machining.”

Lothar Glasmacher, head of business additive and process technology at ModuleWorks, said: “Working in close cooperation is the best way to get the most out of our combined technologies and it is great to see how our optics kernel helps our customers to build innovative, ‘state of the art’ solutions at the forefront of ultra-precision machining.”