Leader Chuck International

Leader Chuck International recently used the

GTMA’s Manufacturing Solutions Conference 2022, held last month in Ireland, to launch its latest product, the Norgren Adaptix vice jaws, impressing visitors looking to improve productivity and eliminate waste from their machine shops and toolrooms.

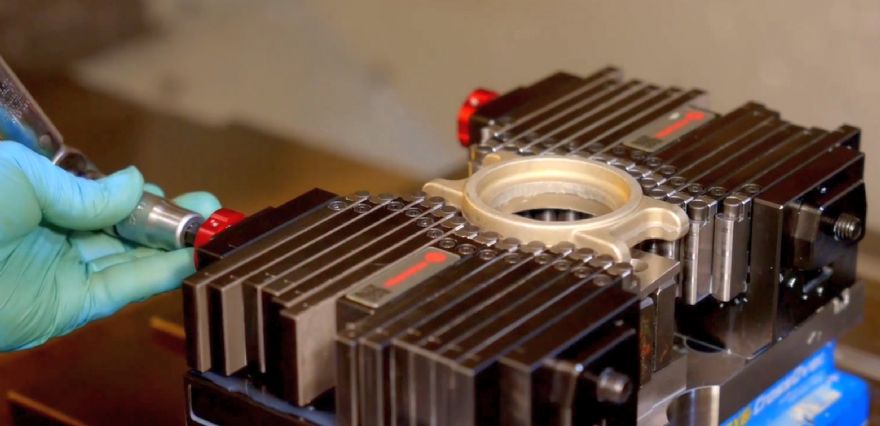

The vice jaws are a ‘revolutionary’ new method of transforming the way machinists can hold and grip parts for milling. With sliding fingers, they can be adapted to any part geometry to provide the necessary clamping forces to hold workpieces, slashing the time and cost involved in the design and development of vice jaws or bespoke fixturing.

Designed to be as robust as standard vice jaws with regards to high clamping forces, repeatability and toughness, Adaptix vice jaws offer more flexibility as ‘fingers’ adapt to the unique part shape to provide time and money savings and simplifying the overall clamping process.

Leader Chuck International managing director Mark Jones said: “For many, the challenge of securely holding shaped material requires vice jaws machined to match the workpiece geometry; whether it is a cast or forged billet, a pre-machined part for Op 2, or even a component being repaired or reworked. Every production or workshop manager knows it takes time, to produce a CAD file or drawing, obtain the materials for the bespoke jaws and then machine them. All these steps have to be taken before the cutting of a part can begin and the company can start making money.

“With the Adaptix vice jaws you simply set the fingers against the workpiece and lock them in position and you can be cutting material within a few minutes compared to half a shift lost to producing machined bespoke jaws which improves productivity — there is no waste, as the vice jaws can be reset time and time again to suit any job that comes in.”

The centre fingers are locked and used to datum stop against the workpiece before the remaining fingers are simply positioned forward and locked in place with a side clamp. From a one-off part to low-volume batch runs, the Adaptix vice jaws can support any milling operation, and there is no need to store boxes full of machined jaw inventory ‘just in case’ a job comes back again.

Mr Jones continued: “Resetting the Adaptix vice jaws is so quick and easy and it eliminates the need to hold jaw material stocks. In addition, the design of the vice jaws allows increased cutting tool access as the fingers can be repositioned during the machining cycle (with the machine stopped) to provide clearance if it is required on certain locations — this could further save an extra set-up and operation.”

The exchangeable tips of each finger can be replaced if they are damaged or sacrificed during the milling operation and are available in various materials, including aluminium, steel, plastic and brass. This facilitate the clamping of different shapes, step profiles and workpieces or components where the surface finish is a key characteristic, all with pinpoint accuracy and repeatability.

Free 30-day trialLeader Chuck International is so confident in the gains presented by the system that it is now offering a free 30-day trial for any company that meets the product mix criteria; and is currently producing soft jaws and wasting valuable machining time.

Mr Jones added: “For any machining operation relying on profiled jaws the time, material and set up savings that can be made results in an ROI that will be measured in a matter of a few weeks. Simply use the Adaptix vice jaws free for 30 days, and then purchase or return them.”

“Adaptix vice jaws are especially well suited to companies that have high product mix CNC production in low volumes; are in the rapid prototyping arena; and manage assembly/bench deburring and run inspection processes.

For all manufacturing businesses in technically demanding sectors operating high-end CNC production equipment, such as expensive three-axis CNC machines, where machine uptime and fast job turnaround is of the essence, this workholding solution is ideal.

He concluded: “With the drive for businesses to reduce waste and maximise efficiency, as well as address the current raw material supply chain issues of exponentially increasing costs and scarce, inconsistent availability, the Adaptix vice jaws provide an elegant solution to age-old problems and addresses all of these business performance goals.”