Seco

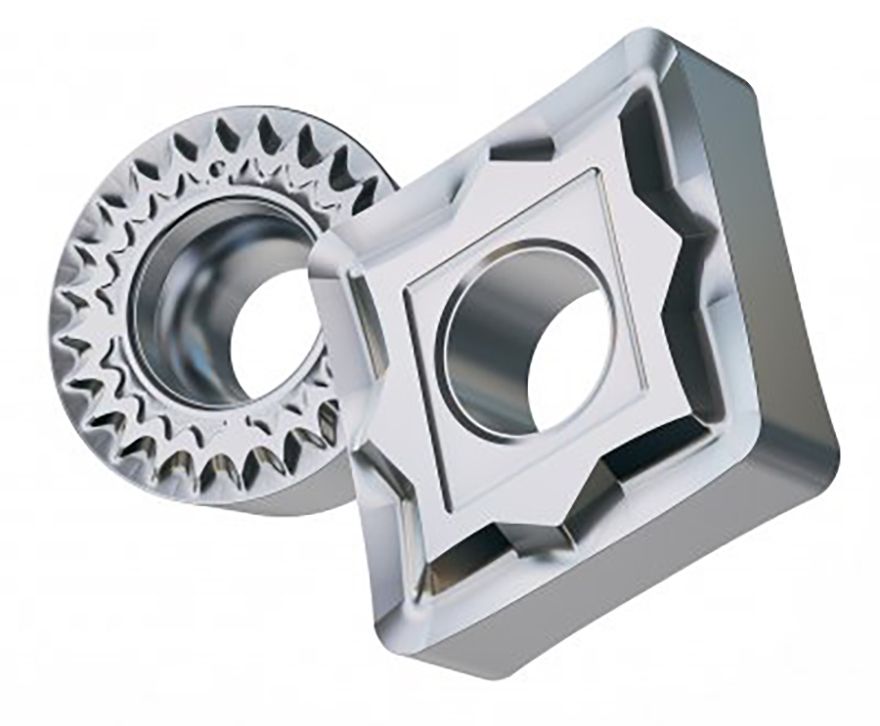

Seco has launched TS0501, a Duratomic finishing insert grade engineered for exceptional performance in turning modern high-hardness and heat-resistant superalloys as well as traditional materials such as Inconel 718. Designed for lights-out machining, TS0501 delivers unmatched tool life, surface finish, and reliability in demanding aerospace and energy applications

The insert’s wear resistance and thermal stability make it ideal for industrial sectors where component integrity is critical. The TS0501 insert is available in a range of geometries and chipbreakers to suit various finishing needs, and is fully compatible with existing toolholders, ensuring a seamless upgrade path for production lines.

Mikael Lindholm, global product manager of General ISO Turning, said: “When you are machining modern, high-hardness aerospace components, there is no room for error. That is exactly why we developed the TS0501 — to give manufacturers a tool they can trust to deliver flawless finishes, also on superalloys, shift after shift, even when no one’s watching the machine.”