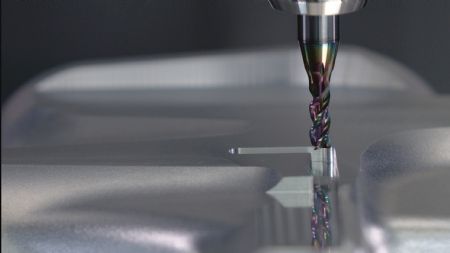

The Guhring RF 100 AluPro Micro

The Guhring RF 100 AluPro MicroTo support the demand for ‘lightweighting’ in industry sectors such as e-mobility, aviation and automotive, Birmingham-based

Guhring Ltd has introduced the new RF 100 AL range of end mills designed for the machining of ISO-N materials. This new family of high-end solid carbide milling cutters are available in diameters from 1 to 25mm. Part of this new line is the new Guhring RF 100 AL Micro that sits at the micro end of the spectrum.

Available in all popular diameter increments from 0.5 to 3mm with cutting lengths of 2.5xD and 5xD, this micro-precision milling cutter impresses with very high material-removal rates that can reduce cycle times by up to 76% when compared to conventional small end mills. Excellent surface finishes and burr control complement this productivity improvement, while the process reliability concerns are eliminated through the tool’s intelligent design.

The RF 100 AL Micro has an ultra-thin Carbo+ coating that reduces wear and increases machining performance and extends tool life, crucial in the micro-diameter range where tool integrity is key. The new round bevel chamfer delivers smooth surface finishes and strengthens the integrity of the cutting edge to prevent edge chipping and tool breakage. With four or six through-coolant channels incorporated as part of the innovative GühroJet internal cooling system, chip removal is reliable, efficient, and it prevents the re-cutting of swarf, even in the deepest of cavities.

Available with either corner radius or corner chamfer configurations, the RF 100 AL Micro offers flexibility for the end user by supporting ramping, slotting, trochoidal milling and plunging. The RF 100 AL Micro demonstrates significantly enhanced machining performance at both medium and high speeds, making it ideally suited to the varied demands of modern production environments. Very high process reliability is ensured through perfected cooling and chip removal capabilities and the highly stable three-flute configuration.

Pictured left: The new Guhring RF 100 AL Micro

Pictured left: The new Guhring RF 100 AL MicroMeanwhile, the RF 100 AL solid carbide milling cutter extends Gühring’s aluminium machining expertise across standard diameters from 1 to 25mm. Like the Micro series, this flexible three-flute cutter can be used to machine a range of materials, including aluminium, non-ferrous metals and plastics. Capable of delivering a 30% increase in machining performance, real-world application data demonstrates the RF 100 AL’s ability to reduce machining time by 59% and generate tool life improvements of 54% compared to similar solutions.

The nano-polished round bevel support chamfer represents a breakthrough in milling technology, enabling the RF 100 AL to achieve the tightest tolerances and optimum performance levels. This precision three-flute geometry presents a large polished flute profile that delivers extended tool life and superior chip removal characteristics.

Moreover, the reinforced core provides exceptional stability, particularly important when machining thin-walled, vibration-sensitive parts as well as cutting at more robust machining parameters. Available with short, medium and long reach variants with a range of neck clearances offered, the series offers flexibility for profiling and machining difficult-to-access surfaces.

With a diameter range from 1 to 20mm with an extensive selection of corner radii from R 0.1 to 4mm, the RF 100 AL demonstrates its suitability for application requirement. The RF 100 AL is also available with Guhring’s advanced Carbo+ coating option, making it ideal for dry and MQL machining.