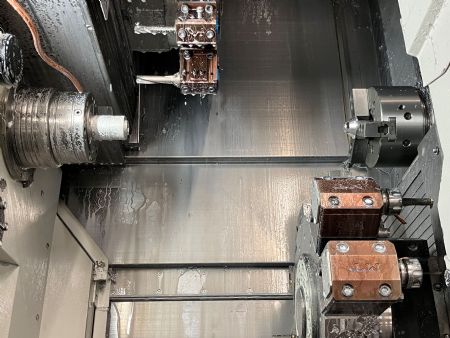

WT150II in action at Medley Precision’s Mansfield facility

WT150II in action at Medley Precision’s Mansfield facilityWhen Mansfield-based

Medley Precision Ltd won a contract to produce fire suppression assembly systems, the sub-contract manufacturer was initially producing the parts on a single-spindle turning centre. However, as the required quantities quickly escalated, a better solution was needed and the company selected the Nakamura-Tome brand for a solution which is supplied in the UK by the Wellesbourne-based

Engineering Technology Group (ETG).

Like many sub-contract manufacturers, Medley has a plant list of high-end machine tools that reflects the quality demanded by its customers in the offshore, power generation, rail, medical, aerospace and defence sectors. With the aluminium fire mist nozzle systems consisting of four components, the initial requirement was for 200 parts per month — a volume sustainable for the existing turning centre. However, the volume soon expanded from 800 parts to 6,000 and an alternative solution was urgently needed.

Medley production manager Stuart Solomon recalled: “We looked at a sliding-head lathe, but one of the parts in the assembly was over 50mm diameter — beyond the realm of a slider. We then looked at a range of machines from other leading suppliers, but it was the pedigree, quality and the price-to-performance ratio of the Nakamura-Tome brand that attracted us.”

The Nottingham company purchased a twin-spindle twin-turret Nakamura-Tome WT15II turning centre at the start of the Covid-19 pandemic to fulfill the monthly order.

Mr Solomon said: “For us, having the facility for one-hit ‘lights-out’ machining via a bar-fed turning centre was crucial to our investment decision and moving from a chucking single-spindle lathe to the Nakamura WT150II was a complete revelation. On the four parts, we more than halved the cycle times. The cycle time for the aluminium nozzle body was cut from 14min to 6 while the time for the other three parts were cut from 8, 6 and 4min to 4, 3 and 2min respectively. But this was not just about cycle time improvements, we wanted to create a stable and efficient process.”

The results were immediately evident. Medley went from one operator permanently located on the single-spindle lathe to one operator covering two machines, while the quality and consistency of the parts were vastly improved, as were the surface finishes. The same Nakamura stability that improved surface finishes and consistency also prolonged tool life significantly with operational costs falling sharply.

Mr Solomon continued: “With the cycle time savings, we could also introduce a de-burring cycle for each part and still be more than 50% faster than before. The deburring cycle eliminated the need for the parts to be put through a post-machining rumbler process to deburr parts. Our operator would put 200 parts per hour into the rumbler for deburring while running a single-spindle machine full-time. Not only have we eradicated this additional process, our consumable costs and the energy efficiency of running one machine instead of two is evident.”

With the first Nakamura-Tome WT150II proving such a success for Medley, the company once again turned to ETG when the order books in the turned parts department continued to bulge. As Mr Solomon reflected: “With the first Nakamura dedicated to 24hr five days a week production of the fire suppression system, we were noticing our remaining single- and twin-spindle turning centres were increasingly close to hitting full capacity — we needed to invest in another Nakamura.”

The East Midlands manufacturer was witnessing a surge in rail work with an increasing demand for fuel systems and associated parts for trains in batches of more than 100 as well as an increase in high-value oil and gas exploration parts such as flow regulators and pins in varying quantities from 20- to over 150-off. Medley specified the Nakamura WY150F, a turning centre with a larger footprint and work area than the WT150II — a footprint that accommodates Y-axis cutting on both the upper and lower turrets.

Confirming this, Mr Solomon said: “The Nakamura WY150F is a slightly larger machine than the WT150II, but it offers additional capabilities. The machine was only commissioned in September and we are already seeing the benefits of this. We swapped the single-spindle machine out and replaced it with the WY150F, as the single spindle no longer meets our profile for a turned parts machine.

While we can acknowledge that the single-spindle turning centre is no match for a twin-spindle Nakamura in productivity terms, we are realising the true value of the Nakamura WY150F, as we are now transferring parts from our other twin-spindle turning centre.

He continued: “We have just moved a part from our other twin-spindle machine to the Nakamura WY150F and the Nakamura has cut the cycle time from 15min to less than eight on a brass component for the rail industry. This cycle time saving is being achieved by hitting both sides of the part at the same time by using the upper tooling turret on the main spindle and simultaneously hitting the back end of the part in the sub-spindle with the lower tooling turret.

By identifying this saving, we will be gradually moving more of our volume components to the new Nakamura and moving our lower batch quantity work to the single-turret turning centre. Another factor that is making the Nakamura perform so well is the impressive technology and software within the control panel as well as the Hainbuch workholding system.”

With the first Nakamura WT150II turning centre dedicated to producing a family of fire suppression components and the second Nakamura WY150F rapidly churning its way through the capacity for Medley, the reduced lead times and improved component quality is bringing more work to the sub-contract manufacturer and a futher Nakamura machine could soon be on the cards.