Established for about 20 years, Market Overton-based

Hi-Spec Precision Engineering Ltd has evolved rapidly over the last decade to become a renowned sub-contract manufacturer encompassing capabilities ranging from conventional and CNC machining to grinding, lapping, honing, welding and fabrication, hydraulic pressure testing and assembly. The company, which has also embraced the latest automation and CNC technology with robots and multi-pallet three- to five-axis machining centres to drive growth and productivity, now has 15 CNC machines.

The work at Hi-Spec ranges from agriculture and aggregate to construction, motorsport, fluid power — and electric guitars (the company is renowned in the music industry manufacturing custom precision-crafted electric guitars —

www.graingerguitarparts.com). Components produced include hydraulic valves and cylinders through to equipment for the quarry and aggregate industry, with volumes from prototypes and small batches to production runs of over 10,000.

Hi-Spec’s investments in the latest technologies and automation now sees the 10-employee business having two machinists running eight machining centres and another two machinists running six turning centres; the remaining six employees undertake tasks such as fabrication, inspection, store keeping and assembly.

This lean approach to operating and the effectiveness of its investments has seen the company increase turnover by more than 40% in recent years without increasing staff numbers. The latest acquisition was a Matsuura MX330 10-pallet five-axis machining centre, along with CAM software from Bicester-based

Open Mind Technologies UK Ltd.

Hi Spec already had a four-axis multi-pallet Kitamura Mycenter and Hurco three- and five-axis machines, but it was the need to increase its five-axis capabilities that led to the installation of the Matsuura machine in the first quarter of 2022. At the time, Hi-Spec was using a ‘well-known’ three-axis CAM system that was sufficient for many of its machine tools and the four-axis Kitamura; the five-axis Hurco offers easy-to-use conversational programming and required only occasional five-axis CAM programming.

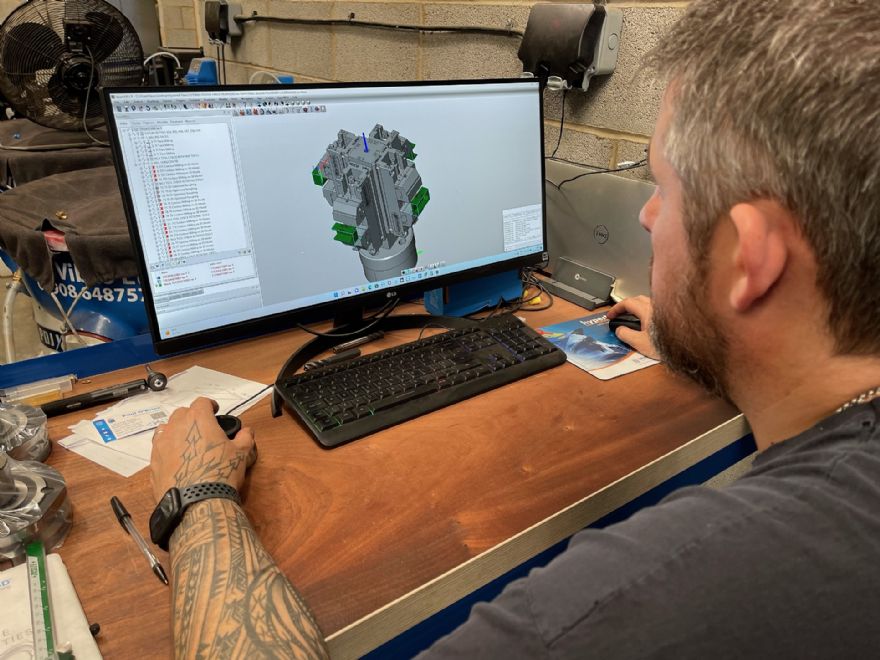

Need for upgradeHowever, Hi-Spec’s existing CAM system was unreliable. Darren Grainger, the company’s founder and managing director, said: “Our CAM system had very poor support and would occasionally crash or fail to ‘boot-up’. We managed for a while, but with the Matsuura machine ordered we knew we had to up our game regarding CAM software; and while we looked at several systems and had some very insightful demos, hyperMill immediately appealed both my brother and me. The demo showed the software’s user-friendliness and capabilities, and it clicked into place.”

Hi-Spec bought one seat of hyperMill a couple of weeks before the arrival of the Matsuura machine and “we haven’t looked back since. We had our training and set up the post-processors for all our CNC machines. There was a learning curve, but the Open Mind team supported us all the way. Initially, we probably called them three of four times a day, but nothing was too much trouble for them. We are now progressively applying the software to our other machines.

“Furthermore, the strategies in hyperMill have drastically improved our cycle times and surface finishes; they have also reduced our cutting tool consumption and costs, freed more positions in the tooling carousels and enabled us to look at how we can programme jobs differently.

“An example is our use of five-axis cycles where we wouldn’t have considered them previously. This highlights the ease of use, our confidence in HyperMill, and the benefits of the different strategies available. For example, we are now using the five-axis ‘swarf cutting strategy’ that uses the edge of a standard end mill to apply chamfers and forms. This is far easier than using 3+2 machining; and by creating multi-function use for standard tools, it reduces both our tooling inventory — and the need for special or additional tools in the tooling carousel.”

Barrel benefitsHi-Spec is also benefitting from the use of barrel cutters, as Mr Grainger highlighted: “We have started using barrel tools and they are improving our cycle times massively, thanks to larger step-overs when compared to ball-nose tools. On a wedge-type component for rock crushing machinery, we have applied the barrel tools in place of ball-nose tools. On one feature, a ball-nose tool had a cycle time of 12min; by changing to the barrel tool we reduced this to less than 4min — and the surface finish is significantly better.

“We previously had a cycle time of 45min per part, but the application of barrel tools and other strategies within hyperMill have cut this to less than 30min — a significant saving when producing a batch of 200 parts with a further 100 in the pipeline.

“Another feature we are using is the five-axis ‘drilling strategy’, which interpolates the job around a tool, thereby allowing us to use a standard end mill to drill holes of any diameter. This strategy means there is no need for large drills and the associated costs of multiple drill sizes; it also negates the need to drill pilot holes and frees-up positions in the tool carousel. Additionally, this method of drilling is more forgiving on the machine tool as we no longer use large drills that draw a lot of power.”

Mr Grainger concluded: “Even collision avoidance is a significant benefit, showing everything in the work area from the workholding to the tool configuration — a capability that gives us astounding confidence. In some instances, it is almost ‘too good’. For example, if we programme an 8.7mm-diameter for an 8.5mm hole due to a customer error on the drawing or model, hyperMill will identify the error as a collision.”