Updates to imcenter software provides greater automation and increase understanding of product performance prior to physical testingSiemens Digital Industries Software

Updates to imcenter software provides greater automation and increase understanding of product performance prior to physical testingSiemens Digital Industries Software says its latest release of Simcenter software for mechanical simulation helps streamline electrification engineering projects, assists new aircraft meet margins of safety, simplifies durability testing across many industries — and ‘much more’.

Jean-Claude Ercolanelli, Siemens Digital Industries Software’s senior vice president, simulation and test solutions, said: “Addressing complex engineering challenges such as developing products that are more powerful, yet greener, lighter and stronger, requires a fully integrated CAE solution. The latest release of Simcenter offers a host of powerful enhancements to help engineers meet those challenges efficiently and significantly faster than ever before, whether that is getting tyre contact simulations solved 45% quicker or reducing airframe structure pre-processing by up to 80%. The highlights in this release are applicable across all industries and workflows and bring new capabilities to the Simcenter family of products.”

For example, Mr Ercolanelli says those exploring additive manufacturing (AM), build process simulation is a must, particularly when dealing with metals-based powder-bed fusion production methods. “The complex nature of these processes usually requires an AM engineer to collaborate with an experienced CAE expert. The latest release of Siemens’ Simcenter 3D software introduces a simplified application for simulation of the powder-bed fusion (PBF) build process that is easy to use for engineers without in-depth CAE expertise.

“Using a robust voxel-based mesh in the background, the software can quickly model and simulate the PBF build process, allowing engineers to gain a good understanding whether a part will build successfully; and following on from the introduction of the ability to launch simulations on remote HPC (high-performance computing) systems directly from within Simcenter 3D, engineers can now review simulation results directly from the Remote Simulation interface. This helps engineers determine if simulation studies ran correctly before transferring large results files back to a local workstation for in-depth evaluation.”

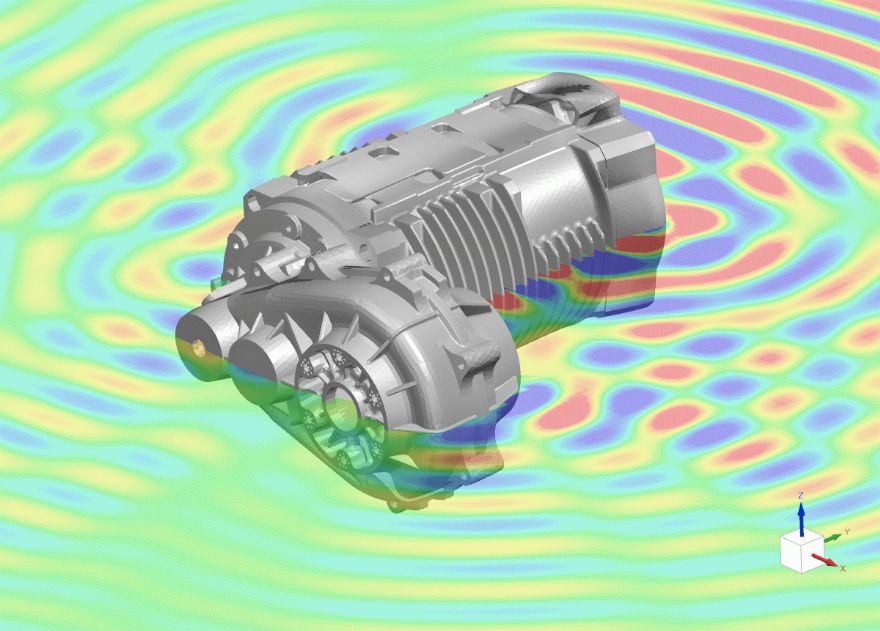

Electrifying automotiveMr Ercolanelli says electrification is a major trend throughout the automotive industry, with the development of new electric vehicle (EV) powertrains tending to be broken into ‘silos’ for e-motor design, transmission analysis, NVH and acoustics, adding that Simcenter mechanical simulation tools can help vehicle manufacturers break these silos by helping critical load, design, and model information to flow easily between each of these disciplines for EV powertrain development.

“Additional new capabilities in this release improve simulation of other automotive applications from NVH, to tyres — and even windscreen-wiper performance. For example, the new contact pattern display in Simcenter 3D helps analyse wiper contact patterns without the need for costly and time-consuming physical testing.

“Moreover, the latest release of Siemens’ Simcente Tire software has an updated road contact algorithm to reduce the large amount of road data exchange required to build the high-fidelity tyre models required for driving simulators, allowing the use of high-fidelity tyre models in real-time applications.”

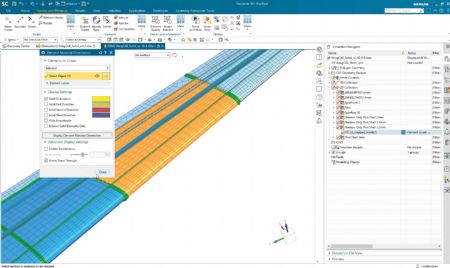

For the Aerospace industry, new capabilities reduce the number of models needed to simulate the behaviour of thin aircraft skins and perform ‘margin-of-safety’ calculations more quickly than ever before. For example, new standard calculation templates have been added to the margin-of-safety analysis tools within Simcenter 3D, allowing the engineer to simply select the geometry to apply calculation to, removing the reliance of custom script development and the associated maintenance costs.

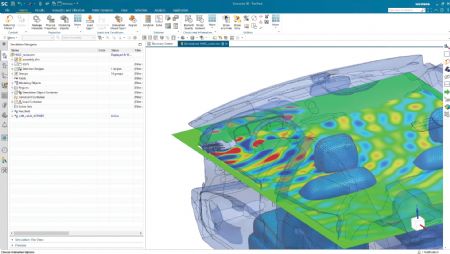

Meanwhile, Nastran is a new capability in Simcenter software that helps airframe engineers working with thin skinned airframe structures that have different stiffness behaviour depending on the load case (see picture on the right). Now, a single model represents an airframe structure, reducing simulation pre-processing time by up to 80%. Also addressed are liquid-fuel ‘sloshing dynamics’ in storage tanks. For aircraft, this helps to predict slosh frequencies and hydro-elastic modes, although this capability can also be applied to evaluating sloshing in large ships (cargo, ballast or fuel tanks), automotive and rail applications — and many other industries.

Predicting durabilityFor the industrial machinery industry, machine uptime is the prime driver, but machine manufacturers often lack the time or resources to physically test their machines to their limits. Mr Ercolanelli says Simcenter can help with new capabilities that help predict durability without the need for specialist knowledge. “For example, Simcenter 3D overcomes the need for separate toolsets and knowledge for proper durability by streamlining and automating strength analysis; it can also automatically calculate the parameters needed to adhere to the industry standard FKM guidelines, thereby allowing engineers to conduct durability analysis directly from their stress analysis results.

“Furthermore, industrial machines often have rotating shafts that turn at high speeds and can vibrate; and while engineers use rotor dynamics simulation and Campbell diagrams to understand the vibration frequencies at various operating speeds, these are only applicable to linear systems. When working with non-linear bushing systems, Simcenter 3D allows the calculation of complex modes during a nonlinear harmonic response to generate a Campbell diagram so that critical speeds of a nonlinear system can be assessed, providing a greater level of understanding of complex rotating components.”