BalTec

BalTec cold-forming machines are regarded worldwide as the most advanced technology to manufacture safe mechanical connections. Since 1968, over 46,0000 machines have been produced by the Switzerland-based company for use in a wide variety of industrial sectors, and many are still in operation today.

As a leading supplier of high-quality riveting and roller forming machines,

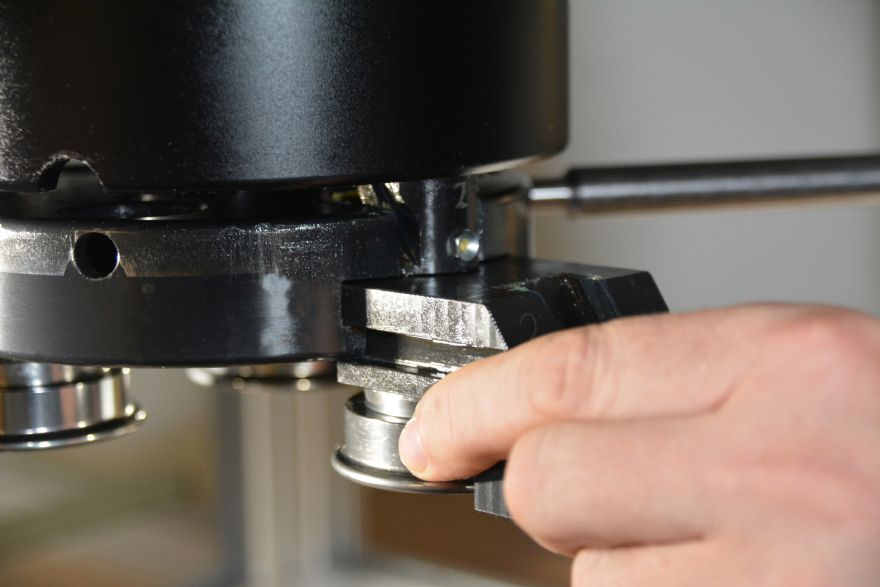

BalTec, which is represented in the UK by Reading-based BalTec (UK) Ltd, has introduced the new CNC-controlled ELECTRIC EA30 with three axis, the world’s first roller forming machine with servo-controlled articulation. With three individually programmable servos, the ELECTRIC EA30 can execute a variety of profile shapes in a single stroke.

The forming capabilities include traditional roller forming, articulating roller forming, 3-D articulating roller forming, and crimping. What makes the ELECTRIC EA30 unique is its servo-controlled radial motion, which delivers significantly higher precision and control compared to conventional solutions that require manual adjustment of a mechanical stop.

Another striking feature of the ELECTRIC EA30 is its slim design — all three servo motors are aligned within the unit, making it well suited for integration into automated production lines with limited space. Moreover, it can also be used as part of a stand-alone work cell for prototyping or low-volume production where frequent changeover of nests and programs may be necessary.

The advanced HPPi software of the ELECTRIC series allows programming and quick adjustment of the forming process using the user-friendly HMI control. The HPPi software monitors all aspects of the forming process and stores the relevant process data. Exporting the data through an industrial data interface (OPC/UA) enables integration into higher-level production management systems.

The primary advantages of this innovative technology are the great flexibility in forming, the programmability and control of the vertical, radial, and rotary motions, and the real time feedback of the forming process parameters. Also, this technology can significantly reduce cycle time compared to conventional, mechanical solutions that may require multiple forming steps and machines to produce one finished part.

BalTec Group CEO Domenico Mollo said: “We are very pleased that with the ELECTRIC EA30, we can again demonstrate our core competence in machine tooling. With this innovation, we are creating entirely new possibilities for our customers to individually design components according to their specific requirements and to adapt them quickly and flexibly should their needs change. The convenient and simple handling based on the principle of CNC-controlled machine tools also offers significant economic and ecological advantages.”