EMO Hannover

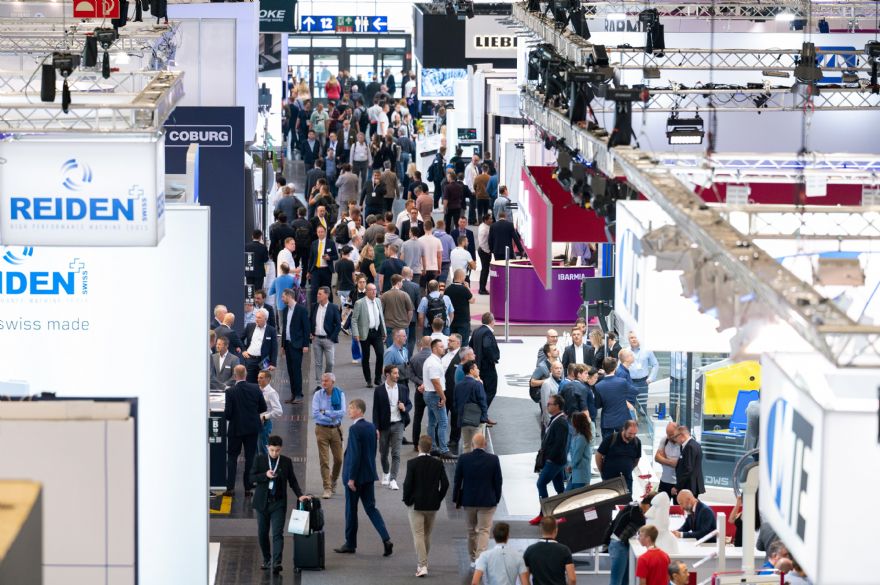

EMO Hannover, held last week, once again provided a perfect platform for top-class technical innovations to the many visitors from around the world.

EMO commissioner General Carl Martin Welcker, said: “We saw everything here required for the future of production — new solutions for automation, for networking within the factory and for sustainable production. When digitalisation finds its way into the factory, there is no end to the potential for new solutions and increased efficiency. This was impressively demonstrated by the exhibitors and there was a positive mood at the event, despite the tense economic situation.”

Around 1,850 exhibitors attended, with roughly 70% coming from 45 different countries, led by China, Italy, Taiwan, Switzerland and Japan. Of the approximately 92,000 trade visitors, 54% came from 130 countries. Here, the five largest visitor countries were Turkey, China, the Netherlands, Italy and Poland, while around a third of the trade visitors came from Asia.

Günter Szerenczés, member of the executive board at Israeli tool manufacturer Iscar, said: “

EMO is once again a triumph, attracting a highly international audience from a wide range of industries. Visitors have been specifically asking about innovations.”

The visitor survey reveals that 30% of visitors gave “obtaining information about innovations and trends” as their top priority. A further goal was finding solutions to specific problems. Dr Matthias Klein, EMAG Group’s CSO said: "We have seen an overwhelming level of interest in the innovative solutions and machines of the EMAG Group.

In particular our solutions presented for machining electric vehicle powertrain components met with great interest. Overall, we are more than satisfied with the response we received.” In a survey, over a third of visitors cited skills shortages as a key issue for the industry, while almost a quarter mentioned digitalisation and networking, and they were able to find just what they were looking for at the exhibition.

There was an abundance of robots on display at

EMO, proving that it is no longer necessary to have programming skills in order to use collaborative robots (cobots) for different applications such as loading and unloading, quality control, painting, washing, as well as connecting to measuring devices. Furthermore, many of the cobots were equipped with sensors that mimic the human sense of touch. allowing them to compensate for workpiece tolerances or work around obstacles in the available workspace. In collaboration with employees, this facilitates enclosure-free operation, for instance. Nils Tersteegen, Fanuc’s marketing manager, said: “Cobots are continuing to enjoy rising popularity in manufacturing, especially in smaller companies that are now struggling to find staff.”

Connectivity in focusAnother focus at

EMO was connectivity. The main emphasis here was on the open exchange of data – based on OPC UA, under the umati umbrella. The ability to retrieve large amounts of data from digital controls without affecting the process was a key factor here. The availability of transparent process data is crucial for process monitoring and related quality management.

Meanwhile, the future of sustainability in production was high on the agenda for 68% of visitors. International delegates accounted for 75% of this group, meaning that they were more strongly represented than their German counterparts. A key aspect was efficiency — the Product Carbon Footprint for example indicates the level of carbon emissions during production and provides customers with detailed information on what indirect emissions the tools they use contribute to their overall carbon footprint. Another example is the structure of spindles which are designed for energy efficiency and not primarily for maximum performance. Finally, cooling lubricants can be used for longer through monitoring and filtering.

Dr Hubert Ermer, managing director for products and markets at Dr Johannes Heidenhain GmbH, said: "Digitalisation and automation are continuing to develop at a rapid pace. The overall aim is to ensure reliable manufacturing processes. This increases productivity while also reducing the carbon footprint.

EMO has given us a platform to discuss the specific challenges of transformative manufacturing processes with our customers and to provide them with full support."

More than half of the visitors to

EMO Hannover 2023 attended for the first time, according to the organiser, which dovetailed nicely with the exhibitors’ goal of attracting new customer business.

Dr Karsten Röttger, CEO at Ecoroll AG, said: “Many visitors became aware of us for the first time. They hadn’t even considered the possibilities of mechanical surface finishing, but our tools allow them to meet the increasing product quality requirements and higher demand for sustainable products.”

Around 20% of the exhibitors were also at the event for the first time. Representing this group, Jörg Rommelfanger, head of ABB’s robotics division in Germany, said: “

EMO provided the ideal platform for us to showcase our latest technologies and solutions for the industry. These included a machine-loading cell specially designed for the fast and automated removal of randomly arranged workpieces. There was tremendous interest, and the numerous conversations and demonstrations we conducted were fruitful and inspiring.”

EMO is a trade fair for executives and decision-makers from the mechanical engineering, automotive and supplier industries, metal processing, precision mechanics, optics, the aerospace industry and many more. Almost 60% of the visitors were executives or came from top management and just under half had decision-making authority for purchasing and procurement. Indeed, half of the trade visitors actually stated that they attended

EMO with concrete investment plans.

On average, these visitors planned to invest just under 3 million euros and more than 25% said they had placed orders at

EMO. Stephan Nell, United Grinding Group CEO, said: “The number of leads is currently at the same level as in 2019. Some machine contracts were also signed directly at the trade show booth.” A further 25% of visitors intend to place orders after the trade show, according to the survey.

Me Welcker concluded: “

EMO Hannover has once again confirmed and consolidated its position as the world's leading trade fair for production technology.”

In 1975, 50 years ago, the first

EMO Hannover took place, and in 2025, it will take place from 22 to 27 September.