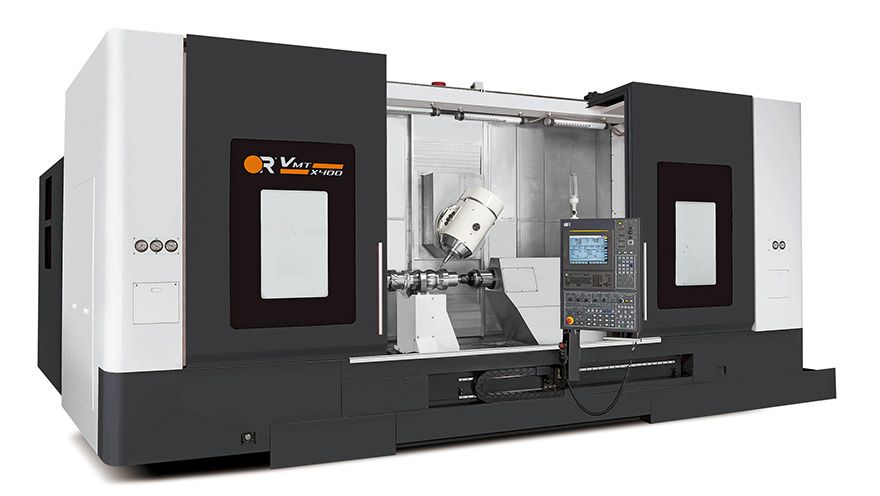

The new Victor VMT-X400 from GM CNC

The new Victor VMT-X400 from GM CNCAvailable in the UK from Oldham-based

GM CNC, the new VMT series offers unparalleled levels of flexibility and capability for ‘one-hit’ machining of the most demanding components while incorporating the stability, precision and rigidity that is the hallmark of the Victor brand.

The VMT series of multi-tasking machines are configured with 15kW twin built-in turning spindles and a 22kW swivelling B-axis milling spindle that defines the power, flexibility and productivity of this exceptional new range of machines. Available in four variants that include the VMT-X200, VMT-X260, VMT-X360 and the VMT-X400, the VMT series is considered ideal for everything from the unmanned machining of small complex parts to heavy duty machining of large parts for the aerospace, automotive, offshore and heavy goods industries. With a comprehensive range of standard features and optional extras, all turned part needs are covered with this multi-tasking range.

As standard, the VMT range is equipped with a Fanuc 0i-TF CNC with iMMI, AICC and MGI with a Siemens control as an option, hydraulic chuck with soft jaws, chip conveyor, a Renishaw automatic tool presetter, through-spindle coolant and hybrid lubrication system. The optional list of features is equally generous with steady rest, bar feed interface, part catcher, automatic doors and sub-spindle.

All of this can be configured upon the industry’s most robust and stable machine platform that delivers unparalleled levels of confidence for heavy material removal machining with unsurpassed surface finishes, accuracy and repeatability. This is achieved through an optimally-designed Meehanite cast base that provides a platform for elevated cutting parameters and improved tool life. The result is industry-leading machining performance.

Spacious work envelopeFrom a specification point of view, the VMT-X200 and VMT-X260 are 8 and 10in chuck machines with a 660mm swing over bed and a maximum turning length and turning diameter of 500mm and 1,075mm respectively. This spacious work envelope is embodied by two 15kW 4,200rev/min turning spindles on the VMT-X200 and a 22kW 3,500rev/min main spindle and 15kW sub-spindle on the 75mm bar capacity VMT-X260.

For larger components, GM CNC presents the 12in chuck 3,000rev/min VMT-X360 and the bigger 15in chuck VMT-X400, both provide 30kW spindle power and a bar capacity of 91mm (106mm optional). The largest machines in the range provide an 1,120mm swing over bed and a maximum turning length and turning diameter of 720mm and 2,100mm. All machines demonstrate exceptional flexibility through the 12,000rev/min 15/18.5/22kW high-winding B-axis milling spindle that can rotate through -30/+210deg with an impressive indexing resolution of just 0.001deg. This flexibility is enhanced with a 40-position ATC on the X200 and X260 machines and 60 positions on the larger X360 and X400 variants.

GM CNC currently has a VMT-X200 machine on display at its Oldham showroom in Lancashire. The stock machine has a list of impressive features that include the Fanuc 31i-B5 Plus CNC with a 15in display with simultaneous five-axis machining capability, circular thread cutting, helical interpolation, arbitrary speed threading, automatic doors, part catcher, bar feed interface, 48-position ATC, high-pressure through tool coolant and more. This machine will be available to view from March.