The Axile G8 machines at Rivercircle

The Axile G8 machines at RivercircleAs a manufacturer of purpose-built leak test machines, process automation and special purpose machines and multi-cavity mould tools, Rivercircle Ltd manufactures and appreciates high-quality machines. That is why the Peterborough-based company has invested in two Axile G8 five-axis machining centres. Available in the UK and Ireland from the

Engineering Technology Group (ETG), Rivercircle installed its first Axile G8 in 2021 with the second machine arriving in September last year.

As well as manufacturing special-purpose machinery, the company is also heavily involved in the toolmaking industry for automotive, pharmaceutical and medical applications to name a few. It is the machining of pre-hardened tool steel and larger components in this department of the business that has brought the addition of the two Axile G8 machining centres.

Jonathan Theobalds from Rivercircle said: “We bought our first five-axis machine about five years ago. We were one of those companies that has had three-axis CNCs for many years and we had been to all the shows and looked rather enviously at the five-axis machines, but we could not see one at a price point for us. Eventually we dived in with our first one and then almost surprising to us, 18 months later we introduced a second machine.

“The initial foray into five-axis machines was a big leap for us but we very quickly learnt that actually having a five-axis machine does not mean that you have to have five-axis work on the machine all of the time. Our traditional three-axis work can be done more efficiently and effectively on a five-axis machine. The important thing for our business regarding the selection of the machine was we needed something with power, strength and rigidity. We are machining hardened and pre-hardened tool steel, so we need that capability to get a lot of metal removal quickly at the beginning and then move into the fine delicate cavity work.”

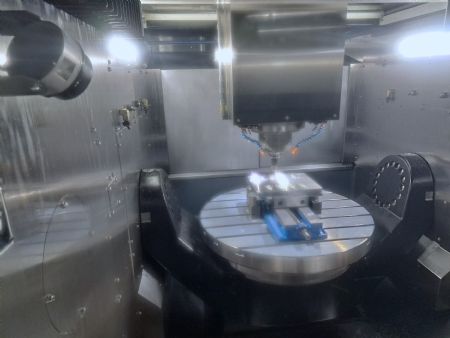

Pictured right: inside the work envelope of the Axile G8 from ETG

Pictured right: inside the work envelope of the Axile G8 from ETGDiscussing one of the big advantages of investing in the Axile G8 machine from ETG, Mr Theobalds said: “With a five-axis machine you are not doing multiple setups, so if we can strap the billet to the machine once and do all the heavy-duty coring-out work and then use the same machine for the delicate finishing, there is a huge efficiency advantage for us there. When we selected our original five-axis, this gantry construction was very important. This gives us strength and rigidity and we are not compromising surface finishes on fine machining or cycle times on heavy cutting.”

The move from a previous manufacturer to the Axile brand was down to capacity — as very few machines can match the versatility, flexibility and speed of the Axile G8 while holding up to 1,350kg on the bed. The smaller five-axis machines have a capacity limit in the realms of 650kg, half the billet size that can be held in the Axile G8.

With the ability to hold 1,350kg on the moving bed of the five-axis Axile G8, Mr Theobalds added: “As machine builders ourselves, we really appreciate how the Axile machines are built. The Y-axis has twin spindles and twin drives the tilting B-axis has a motor on each side — it is not just driven from one side. This gives the machine excellent rigidity and accuracy. Furthermore, the Axile has a powerful spindle with 20,000rev/min and high pressure through spindle coolant. This allows both heavy-duty roughing and high-speed finish machining.”

Top quality componentsAlluding to the benefits of the Axile G8, Mr Theobalds explained: “It has enabled us to produce even higher-tech tooling. So, a lot of the large tools that we have been doing on these machines recently have large bolsters with cores that have to match within microns. The tools produce very thin-walled products that have to have the accuracy to match how those tool cavities interface with the core parts, and this is absolutely essential for our customer to produce a top quality component.

Pictured left: a complex mould tool component machined on the Axile G8 at Rivercircle

Pictured left: a complex mould tool component machined on the Axile G8 at RivercircleHe continued: “We are really proud of the team that we have here. The expertise starts with the design and procurement through to tool path programming and obviously machining then fitting and assembly. It is our job to invest in and utilise the best quality machines to get the best out of the skills of our team. This has led traditional mould making to evolve into precision prototyping of parts and having this five-axis machine where we can do parts in a single set-up rather than multiple setups, has enabled us to get our lead times down which is a requirement for prototyping. Furthermore, it enables us to keep our high levels of precision and quality of toolmaking for those parts. That is the thing that always impresses our customers when they visit us. They know that they are getting mould quality in prototype parts.”

Referring to the user-friendliness of the Axile G8, Mr Theobalds concluded: “We programme our machines off-line with Mastercam and then send the files to the machines. As a predominantly Heidenhain machine shop, the Axile G8 is equipped with the latest Heidenhain TNC640 CNC system that provides familiarity for our team. The Axile G8 is also equipped with the latest software that enables ETG to remotely access, assess and rectify any issues we may have with the machines.

“Additionally, Ian Deacon from ETG has been extremely supportive of any teething issues we have encountered. For the operator, the Axile is fast and efficient and this can also be seen in the machine design. The ergonomic design of the loading doors give easy access to the work area for the operator as well as excellent clear vertical access for large parts that need to be hoist lifted into the machine. Even the tool loading system is horizontal, which makes tool changeovers much easier for staff. Overall, we are delighted with the Axile machines and the service from ETG.”