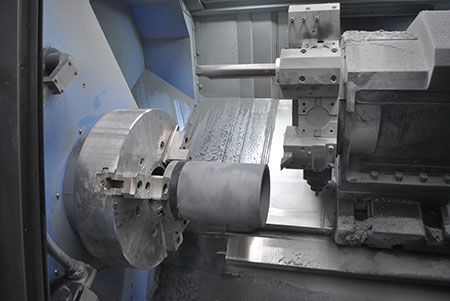

New Puma 700LM II lathe in situ at Tufcot Engineering

New Puma 700LM II lathe in situ at Tufcot EngineeringSheffield-based

Tufcot Engineering Ltd, a market-leading composites manufacturer, has invested in a new Puma 700LM II lathe supplied by

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland. The new, large capacity, multi-tasking lathe comes with a 24in chuck, driven tooling and an advanced Fanuc 0iTP control with 15in touchscreen capability. It is one of the largest CNC machine tools acquired by Tufcot in its 43-year history, and was installed at the company’s 50,000ft

2 facility in Sheffield in April 2024 with the aim of enhancing its service to both and existing and new customers.

Tufcot’s relationship with Mills CNC first began in 2005 with the purchase of its first Doosan lathe – a Puma 240LC and over the last 19 years more investments have followed culminating in an order earlier this year for a new Puma 700LM II and a 21in chuck Puma 4100MC lathe, which is due to be delivered in August. These latest investments will take the number of CNC lathes Tufcot has acquired from Mills CNC to 11 in total.

Turning technology of choiceTufcot’s managing director Greg Majchrzak said: “We have a good relationship with Mills CNC and DN Solutions’ lathes are our turning technology of choice. The high-performance lathes Mills CNC sells and supports are real workhorses — they are reliable and deliver the fast processing speeds and high accuracies we need to meet our customers’ quality requirements and stringent lead time demands.”

Since being installed, the new Puma 700LM II has been busy machining, in relatively small batches, a range of high-precision, large diameter Tufcot composite bushes and bearings for customers in the UK and European marine sectors. These parts, machined to tight tied-up tolerances, often have long cycle times (hours as opposed to minutes) and a range of intricate milled features.

Tufcot is a composite engineering material manufactured from synthetic fibres and thermos-setting resins. Different material grades of Tufcot are available, each with their own defining application-specific characteristics and properties. Tufcot can be supplied to customers in sheets, tubes and rods, but the company’s core business is supplying finished products such as wear pads, bushes and bearings, many of which are custom solutions.

The marine sector is important to Tufcot’s future growth ambitions, and the company has invested significant resources over the years into developing application-specific Tufcot composite grades for a growing number of domestic and international customers operating in the sector.

For example, the company’s specially-formulated Tufcot T100 Marine grade for pintle and pintle rudder bearings, with its high-strength-to-weight ratio, low friction and self-lubricating properties, is now type-approved by an increasing number of global marine classification and certification organisations and associations. Lead body recognition and endorsement of Tufcot composites is a real game-changer and is helping the company grow its marine business.

Discussing the choice of Puma Justin Krebs, Tufcot’s operations manager, said: “Our own knowledge of composites and their application in the marine sector combined with expert insight from our international distributor network and from existing customers, helped highlight significant new business opportunities that we could exploit if we had larger and more sophisticated in-house turning capabilities.”

Turning technology of choiceTufcot always had the capacity to machine large parts on its existing lathes, but the processes involved were labour intensive and required more work handling which impacted the cost-per-part and lead-time fulfilment. The investment in the new large multi-tasking lathe has made large component machining at Tufcot a more viable and profitable exercise.

Mr Krebs added: “Owing to the increased demand for Tufcot composites from new and existing marine customers, it made perfect sense to strengthen our turning operation by investing, in the first instance, in a new large-capacity, high-specification lathe to machine these larger parts.

“As a consequence, we approached a number of machine tool suppliers with our plans and asked them to recommend their preferred machine tool solution and to provide costs. We crunched the numbers and, ultimately, made the decision to invest in a new machine.”

Having gone through what was a comprehensive and detailed decision-making process, Tufcot ultimately opted to go for the Puma 700LM II from Mills CNC. The new machine is a rigidly-designed and built, large-capacity lathe with a 900mm maximum turning diameter and a 3,200mm maximum turning length. It is equipped with a powerful, high-torque 55kW/1,500rev/min main spindle, a 12-station BMT 85P turret with 11kW/3,000rev/min driven tooling capabilities that enables milling/drilling operations to be completed in a single set up, and a programmable, dead centre tailstock for the fast and reliable processing of longer tube, rod and shaft-type parts. To improve in-process efficiencies the Puma 700LM II supplied to Tufcot also featured an automatic tool setter and a heavy-duty swarf conveyor.

Greg Majchrzak said: “The Puma 700LM II can handle large and small parts, and the driven tooling capability enables complex, high-precision features to be machined in a single set up.”

Delivering fast part cycle times and eliminating the need to transfer components between machines has helped improve productivity and process efficiencies, and has enabled Tufcot to win new machining contracts for larger components from new and existing marine customers that, prior to the Puma 700LM II investment, would have been out of its reach.

Future-proofing the businessMr Majchrzak said: “To protect the new business won on the back of the Puma 700LM II acquisition, we also made the decision, at the same time, to duplicate the investment by ordering a new, similarly specified 21in chuck Puma 4100MC lathe. This, we believe, will enable us to continue to meet our production and delivery schedules should the Puma 700LM II be out of action for any reason, such as through planned maintenance interventions or unexpected downtime. In effect, we are future-proofing this new business, and are leaving nothing to chance.”

Tufcot is an innovative company committed to continuous improvement and regularly invests in its people, in its plant and equipment, and in its processes and systems. Mr Krebs explained: “We regularly monitor and benchmark our performance against KPIs to help identify potential production capacity issues and bottlenecks before they become a problem.”

In addition to investing in the two new lathes from Mills CNC, the company has also recently acquired two “state of the art’ CNC routers in 2022 and, in a major development completed at the tail end of 2023, increased the size of its facility with the purchase of additional premises adjacent to its current site. The extra space will enable the company to reconfigure its manufacturing, machining and assembly, stock holding and dispatch operations to meet the anticipated and continuing high demand for its products and services.

Tufcot’s continuous improvement programme also saw the recruitment of Justin Krebs as operations manager in 2020. This has proved to be a key appointment and, through leveraging his extensive machining and composites knowledge and experience, has resulted in the successful implementation of a number of innovations and productivity and process efficiency improvements that have increased turnover and accelerated growth.

The company continues to develop and enhance the range of Tufcot grades it supplies to customers, and is expected to introduce a new ‘super material’, currently undergoing extensive in service trials, into the market later this year. Tufcot was established in 1981 by directors Len Wheat, Elvin Majchrzak and Michael Majchrzak. Previously employed by British Steel in Sheffield, the three directors had over 40 years’ experience in the plastics and composites industry between them.

They initially used their collective expertise and know-how to set up a new company serving the needs and requirements of a relatively small and select number of customers by first producing and supplying them with Tufcot semi-finished products such as laminates, tubes and rods, and later, through machining and supplying them with a range of Tufcot finished products that included wear pads and bushes.

Since these early days Tufcot’s fortunes have really taken off. With demand for strong, lightweight and durable composites increasing, and with composites being recognised and accepted as a real alternative to metal in selected applications, Tufcot is now established as a main player in the market supplying customers in the renewables, mining, agriculture, hydraulics, rail and marine sectors, with high-quality innovative Tufcot products and solutions.