Precision machining with Starrag

Precision machining with StarragAmmann AG changed its strategic business orientation 15 years ago from being a contract manufacturer for the machined switch and track parts to

Ammann Components, a system supplier specialising in complex, high-precision workpieces. Success and growth soon set in — thanks to its employees and their expertise as well as the high-quality machinery, which includesseveral Heckert compact machines. The Swiss precision machinists are expecting a further boost from the recently delivered Heckert H75.

The Ammann family has been involved in blacksmithing and locksmithing since 1732. In 1860, Conrad Ammann founded the first company in the Swiss town of Tägerwilen, a locksmith’s shop with four to six employees that mass-produced wooden drills and agricultural and forestry equipment. This set the foundation for the company, which has now been based in Tägerwilen for eight generations. Throughout this long tradition, the last 40 years have been particularly exciting.

At the beginning of this period, the company entered into a close partnership with an engineering office for switch and track technology — a business that developed spectacularly. Innovative ideas were formed by the Ammann production team. The forging of fastening elements was increasingly accompanied by the machining of cast blanks.

Ammann invested with the first four-axis Heckert machining centre purchased in the early 1990s, it was primarily the two Heckert CWK630 machines purchased in 1999 that met the growing demand for milling capacity. Markus Halder, who joined the Ammann production team in 1999, remembers: “With these extremely stable machining centres, we were able to drive through the cast blanks at high feed rates and remove up to 4mm of chips. This ensured short processing times and ultimately economical operation.” To further increase machining capacity, those responsible invested in a further Starrag machine — the first Heckert HEC 500 entered production in 2006.

Pictured right: high precision parts manufactured at Ammann

Pictured right: high precision parts manufactured at AmmannIn 2008, Ammann AG was no longer working to full capacity for its partner. Mr Halder added: “We proceeded very systematically and drew up a strengths and weaknesses analysis to help us realign the business. We had to find a niche where our strengths compensated for the costs incurred.”

Managing director Paul Ammann was aware of his company’s capabilities: “At that time, we had four engineers with extensive engineering and production expertise, as well as special materials expertise in forged parts. Furthermore, we had excellent machinery.”

Mr Halder continued: “The search for suitable orders was like looking for the infamous needle in a haystack. With persistence, we received our first order from Kuka for the machining of robotic structural parts.” During project meetings, it became clear that the Heckert HEC 500 was exactly the right machine for machining these large cast parts. “We worked closely with the customer on this project and learned a great deal. This success gave us confidence that our Heckert compact machines can not only master heavy-duty machining but also achieve high productivity and process-reliable precision.”

Strategic realignmentAmmann Components was able to establish itself and position itself broadly. Mr Ammann is certain: “In retrospect, our decision to undertake this strategic realignment was exactly the right thing to get our company back on track for success. Our customers appreciate the added value we offer them by developing suitable machining processes for their workpieces. As a result, we have grown from 22 to over 50 employees in the last 15 years and continue to be in an expansion phase.”

Pictured left: high-precision-detail

Pictured left: high-precision-detailTo cope with the increase in orders, the company continuously invested in further Heckert compact machines. Since 2017, a Heckert HEC 500 F has been part of the machinery, predominantly for milling aluminium alloys. The Heckert HEC 500 purchased in 2019 and 2020 is used for heavy machining.

The company boss Mr Ammann emphasised: “These high-precision, compact machining centres are of significant importance to us. Not only do they ensure we meet all component quality requirements, they also give us a high degree of flexibility in terms of workpieces. In our niche, we tend to handle small and medium batch sizes, but they are recurring and have overall project durations of between five and 20 years or even longer.”

Today, Ammann Components describes itself as a system supplier for mechanical components. This primarily includes turned and milled parts made of steel, cast iron and aluminium as well as cast and forged parts. A key area of activity is large injectors and their housings for ship engines or power generators. Mr Ammann continued: One of the most difficult things about machining them is the 350mm deep holes with a diameter of 3mm, which we have to create with a positional tolerance of 0.1mm. When faced with such challenges, we tinker with tools and cooling lubricants until we achieve a process-reliable and economical result on our Heckert HEC 500.”

Defence technology is also a significant customer industry. Whether it is chassis components or undercarriages for tanks — Ammann Components supplies sophisticated parts and ready-to-install assemblies. Socket boards for hydraulics are a speciality. Mr Halder explains: “We mill the sealing surfaces circularly without a shoulder and achieve surface finishes of N5 — on Heckert machines supplied by Starrag, of course.”

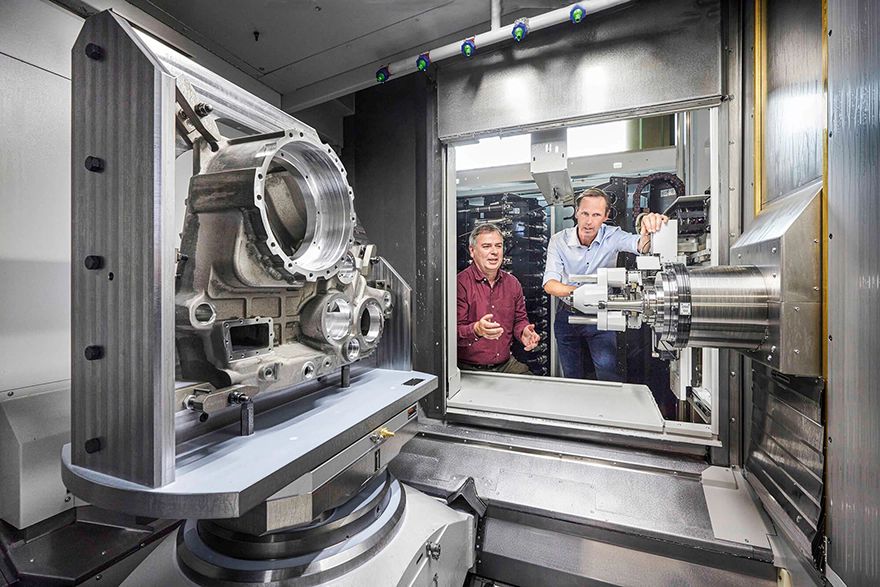

Pictured right: Starrag four-axis machining centres in action at Ammann

Pictured right: Starrag four-axis machining centres in action at AmmannHe continues: “We want to improve with every new machine, become even more precise, even more flexible. But we face stiff competition despite being a niche market, so we cannot price our products arbitrarily. For realistic unit costs, the machines must function reliably and precisely for many years.”

Among the four-axis centres, the Starrag machines always came out on top. What speaks in their favour are the positive experiences users have had over many years, their stable machine design and the consistently high quality has been appreciated by Ammann Components for a long time. It was only recently that one of the first Heckert machines, a CWK630, was replaced after 23 years of continuous use in shift operation. “The investment paid off,” smiles the sales manager, who is also a member of the executive board. He expects a similar outcome from the replacement investment in the new Heckert H75 compact machining centre, which was commissioned in May 2023.

The successor model to the successful Heckert HEC 500 comes with various improvements and promising options. The machine is used to machine large aluminium gearbox housings for which the customer specifies centre distances with a tight tolerance. Aluminium in particular reacts sensitively to temperature differences and every degree means an expansion of 0.02mm for this gearbox housing.

Mr Ammann is also enthusiastic about the spindle with its maximum torque of 950Nm and a speed of up to 12,500rev/min. This makes the BAZ equally suitable for aluminium and heavy machining. To maximise flexibility and keep set-up times to a minimum, the Heckert H75 was equipped with large tool storage. With its four coupled towers, the tower magazine has a capacity for almost 400 tools.

As Ammann Components plans long term with all its investments, the move has already had an impact on the Heckert H75, as Mr Ammann explained: “At the moment, automation is neither necessary nor possible. At the new location, however, we will expand the Heckert H75 and the Heckert HEC 500 with a pallet system to create a low-manpower production system.

“It was therefore important to us that the H75 is fully compatible with the Heckert HEC 500 so that a second set-up station is not needed. As we expected, our partner Starrag was extremely flexible and made the necessary adjustments to the Y-travel as well as the pallet changer.”