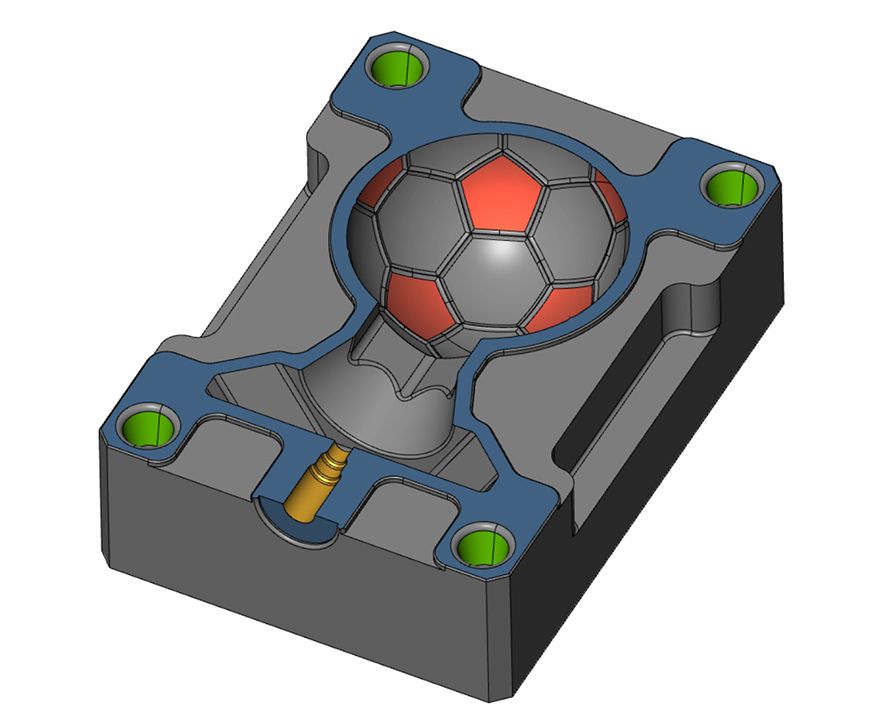

CAM programming is ready — milling will take place live at the AMB to demonstrate the performance of Hufschmied tools. Photo: Hufschmied Zerspanungssysteme

CAM programming is ready — milling will take place live at the AMB to demonstrate the performance of Hufschmied tools. Photo: Hufschmied ZerspanungssystemeGermany-based

Hufschmied Zerspanungssysteme GmbH will be exhibiting at

AMB in Stuttgart from 10-14 September (Hall 3, Stand 3B67). The focus of the presentation at the leading metalworking trade fair will be the Hard-Line milling tool series. To demonstrate the performance of its tools in producing high surface qualities, Hufschmied will be carrying out live machining of a steel injection mould on a Grob G150 five-axis universal machining centre.

Two milling tools from the Hard-Line that are explicitly optimised for machining steels up to 72 HRC are the focus of Hufschmied’s

AMB presentation: HHF667 is an HVPT finishing cutter (high velocity performance tool). Both its special geometry and the TL12 multi-chamfer hard milling coating ensure low wear when machining stainless steels. Its polished chip geometry enables high chip flow rates and increases process reliability against chip jamming.

The second tool presented is the HC643MUT mini-torus milling cutter, the only Z3 mini (from D1 = 0.3mm) on the market. Thanks to its geometry and coating, this tool is also particularly well protected against wear when machining stainless steels. All tools in the series are provided with an individual QR code that refers to the respective digital twin with gauge block and recommends the tools for production processes that are optimised in terms of Industry 4.0.

Process optimiserAt

AMB, Hufschmied will not only be presenting itself as a manufacturer of special tools for certain materials, but also as a process optimiser. With individual consultation and test series in their own technology centre, the machining experts find solutions for the respective challenges that companies face when machining particularly hard, brittle or temperature-sensitive materials, for example.

Christel Hufschmied, managing director of Hufschmied Zerspanungssysteme, said: “In order to achieve the technical and economic optimum of a machining process, the tool and CAM programming must be matched to the material, the shape of the workpiece and the properties of the milling centre. We invite visitors to challenge us — we are sure that we can undercut their previous machining times and top their existing tool life.”

Established in 1991 and headquartered in Bobingen, near Augsburg, Hufschmied Zerspanungssysteme is a manufacturer of high-quality tools for machinable production and friction stir welding. By specialising at an early stage in the machining of plastics, fibre glass materials and carbon fibre, Hufschmied has become a leader in Europe in the development of solutions for new materials. The company is an established system supplier to renowned machine tool manufacturers.

Tools and manufacturing process consulting from Hufschmied are particularly valued in the automotive and aerospace industries as well as in medical technology. The company is involved in numerous organisations, including

Composites United Deutschland e.V. Hufschmied’s manufacturing operations are located in Bobingen, Winterlingen and Sigmaringen on the Swabian Alb. Hufschmied is certified according to ISO9001:2015 (quality management) and ISO14001:2015 (environmental management) and is also the only tool manufacturer with its own diamond coating plant.