Aberdeen-based

Macro Manufacturing Ltd, a precision sub-contract specialist start-up, has invested in a DN Solutions’ Lynx 2600SY new high-performance, multi-tasking lathe supplied by Leamington Spa-based

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland.

The Fanuc-controlled Y-axis lathe was installed at the company’s 950ft

2 facility in April, and is currently being used to machine a range of components for a growing number of customers in a range of sectors including oil and gas, renewables and agricultural.

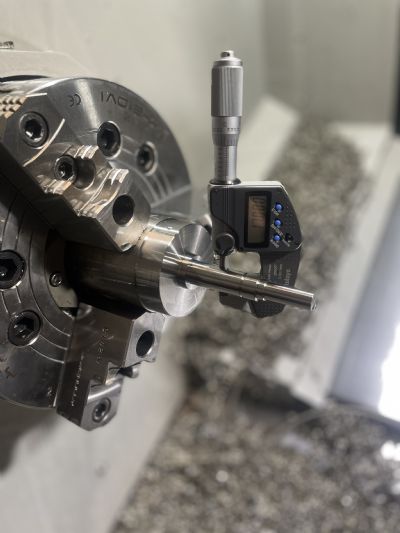

These parts, typically machined in medium-batch sizes, are manufactured from a range of different materials, including stainless steel (316, 316L and 17-4 grades), duplex and super duplex, aluminium alloys, 4140 low alloy steel, exotics that include Inconel and Hastelloy, and some engineering plastics such as Acetyl. Components machined by Macro Manufacturing are also characterised by their complexity with tight tied-up geometric tolerances and exacting surface finish requirements being the norm rather than the exception.

Although relatively small in size, these parts frequently exhibit intricate and delicate features that can only be machined, or can only be machined efficiently and economically, on a multi-tasking lathe.

Matthew Forbes, Macro Manufacturing’s owner and director, said: “The Lynx 2600SY is a high-accuracy multi-tasking lathe that has significantly increased our in-house machining capacity and capabilities and enables us to machine complex parts quickly, in just one set-up. Since its arrival, we have been able to secure new machining contracts from both new and existing customers, and have strengthened our position within a number of customers’ manufacturing supply chains.”

The Lynx 2600SY is the first machine tool Macro Manufacturing has acquired from DN Solutions since the company was established in 2022 and is also the first new machine investment. Like many new precision sub-contract start-ups, Macro Manufacturing had relatively humble beginnings, starting life in a shed on a local farm with initial machining contracts being undertaken on a couple of used CNC machine tools at the company’s disposal.

Mr Forbes continued: “The early days were a challenge. I was still employed full-time at my previous employer, and was having to manage and run the new company in my spare time — during the night and through the weekends.”

‘Biting the bullet’This situation was always intended to be a temporary, stop-gap measure until the company was more established and, after just a few months, Mr Forbes decided to ‘bite the bullet’ and put all his time and effort into making Macro Manufacturing a success.

Mr Forbes is an apprentice-trained, time-served engineer with significant machining experience and he is passionate about engineering and always had the desire and ambition to run his own company. His vision, which is now being realised, is to supply high-quality, competitively-priced precision machined components to customers, and to grow the business through developing long-term partnerships wit them. Part and parcel of these plans was to relocate the business to new premises, and to increase the company’s in-house machining resources.

Macro Manufacturing’s decision to invest in the new Lynx 2600SY was made for a number of reasons as Mr Forbes explained: “Having access to a multi-tasking turning centre would enable us to expand our customer base and to take on more complex, and hopefully, more profitable work. A lathe with integrated Y-axis, sub-spindle and driven tooling capabilities would allow us to machine precision parts to completion in one set-up and avoid the problem of production bottlenecks caused by having to transfer parts between machines. Furthermore, the machine’s ability to run unattended, we believed, would make us more efficient and productive too.”

Having already experienced the power, speed, precision and reliability of a Lynx 2100SY lathe in his previous employment, Mr Forbes approached Mills CNC to enquire about the availability of a, larger capacity, Lynx 2600SY.

Mr Forbes continued: “I liked Mills CNC’s proactive approach. They were interested in our plans and made the investment process simple and straightforward.”

The 10in chuck/81mm bar capacity Lynx 2600SY is a popular and proven compact turning centre equipped with a powerful, high-torque main spindle (18.5kW/3,500rev/min/403N-m), a 6in chuck 4,500rev/min sub-spindle and 6,000rev/min driven tooling capabilities. The lathe also features a +/- 52.5mm Y-axis, a 12-station/24-position servo-driven turret, roller LM guideways and the Fanuc 0iTP control.

The machine supplied to Macro Manufacturing also featured an auto-tool setter, a FilterMist extraction unit and 20bar fixed coolant capability.

Matthew Forbes concluded: “The Lynx 2600SY is a highly productive machine and is ideal for fast and accurate small parts processing. Since being installed, the lathe has been put through its paces machining a range of complex parts, and hasn’t missed a beat. The Lynx 2600SY has made us more competitive, and has been more than instrumental in us acquiring new customers and securing repeat business with many existing ones.”

Macro Manufacturing is not a company that rests on its laurels or leaves anything to chance. In the not-too-distant future, the company plans to relocate again to larger premises, take on additional staff and, as part of its commitment to continuous improvement, invest in more advanced machine tools and ancillary technologies.