Stephen Hogg, Woodbrook Precision managing director (left) with Ceratizit’s technical sales engineer Matthew Darbyshire discussing tooling strategies in front of a 3.5m bed Mazak VTC800/30SR five-axis machine loaded with a Ceratizit ‘Made in Sheffield’ tombstone

Stephen Hogg, Woodbrook Precision managing director (left) with Ceratizit’s technical sales engineer Matthew Darbyshire discussing tooling strategies in front of a 3.5m bed Mazak VTC800/30SR five-axis machine loaded with a Ceratizit ‘Made in Sheffield’ tombstoneThe term ‘one-stop-shop’ is banded around the sub-contract manufacturing industry far too easily, and it is not until you stumble across a company like

Woodbrook Precision Ltd that you can truly understand what a single-source solution provider truly looks like. The Lancashire manufacturer ventures beyond rivals’ services and continually invests in the latest machine tools fully supported by advanced cutting tool solutions supplied by Sheffield-based

Ceratizit UK & Ireland Ltd.

Located in Ashton-Under-Lyne on the edge of Greater Manchester, the plant list at Woodbrook Precision includes a line-up of manual and CNC three- to five-axis machining centres and multi-axis turning centres, from well-known brands including Mazak, XYZ, Leadwell and Bridgeport. The ‘state of the art’ plant list is supported by services such as grinding, plating, shearing, profiling, welding, laser cutting, gear cutting, heat treatment, and powder coating. Rightly proud of its comprehensive services and recent investment in advanced Mazak machines, Woodbrook’s managing director Stephen Hogg says that Ceratizit has been instrumental in enhancing the productivity of its latest equipment.

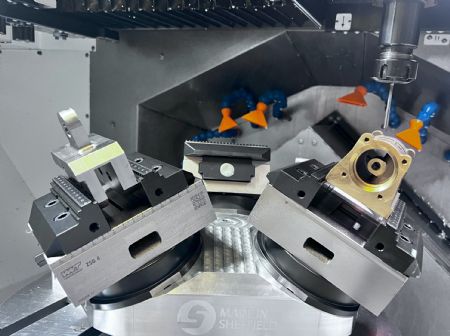

Ceratizit pyramid system on the Mazak CV5-500 at Woodbrook Precision

Ceratizit pyramid system on the Mazak CV5-500 at Woodbrook PrecisionThe second-generation business was established by Mr Hogg’s father more than 35 years ago and when he took over the reins 16 years ago, Woodbrook operated out of a small unit with a single CNC turning centre and a series of manual mills — all supported by various cutting tool vendors, with WNT (a subisidiary of the Ceratizit Group) being one of the many. However, as he has applied his vision and determination to the company, Woodbrook has evolved with a 2018 move to an 18,000ft

2 facility three-times larger than the previous site. Plans are also afoot to add another 10,000ft

2.

This growth has stemmed from the company’s progress in expanding its general sub-contract machining into the oil and gas, aerospace, rail, and motorsport sectors, and Woodbrook has evolved the sophistication of its machine tool purchases to serve these industries. Initially investing in three-axis Mazak vertical machining centres with rotary tables and turning centres with live tooling, more recent acquisitions have included two 3.5m bed Mazak VTC800/30SR five-axis machines and a five-axis Mazak CV5-500. This has seen work for overhead cranes, rail, and general sub-contracting evolve to include aerospace jigs and fixtures, critical subsea valves and manifolds, motorsport brake callipers and engine components.

With an evolution driven by the expanding capabilities of its machine tools, Woodbrook has needed to rely more heavily on the expertise of its cutting tool suppliers. As the business has shifted from machining steel and aluminium to hard-to-machine materials such as stainless, super duplex, titanium, Inconel, carbon fibre and Hastelloy – Ceratizit has emerged to be the cutting tool partner of choice.

Mr Hogg explained: “Over 10 years ago, Ceratizit was one of many suppliers, and as I took control of the business, it became evident that the tooling specialist had the best-performing tools and its level of service was far beyond anything else we had experienced. As we continually ventured into more complex work and more challenging materials, we needed greater support and new machining strategies; Ceratizit’s technical sales engineer Matthew Darbyshire has been with us all the way to provide solutions. It has been seamless, and it is pointless going elsewhere as he makes it so easy and ‘pain-free’ for us.”

Recalling the early days of working with Matt and Ceratizit, Mr Hogg added: “With numerous sales representatives continually calling upon us, we asked Matt for a few tools to trial. The tools initially performed well, but for the relationship to blossom to a position where we now have thousands of Ceratizit tools, well that has been built on tool performance, product range diversity, supply chain continuity and most importantly, technical support, service and trust. I know I can contact Matt via WhatsApp with any drawings and queries and he will quickly deliver the best solution.”

Productivity gains As a machine shop that typically manufactures prototypes in small batches, tracking continuous tooling improvement isn’t always the priority for Woodbrook. However, you don’t have to look far for quantifiable results with Ceratizit products. Mr Hogg continued: “We recently implemented the Ceratizit facing and parting-off tools, and it reduced the cycle time on a 400-off job from 1min 58 sec to 1min 26sec. We also applied the Dragonskin CircularLine DLC-coated solid carbide end mills with impressive results. The Dragonskin tools have cut cycle times on an aluminium part from 3min to 1min 20sec whilemore than doubling our tool life.”

“On another 100-off repeat order stainless steel aerospace fixture, we needed to reduce our cycle times to maximise margins and reduce costs. Matt introduced a Ceratizit’s high-feed indexable end mill, and this reduced our cycle times from 38 to 26min per part, with a tool life improvement of more than 20%. This was a significant saving on a long-running job.”

However, the most significant saving wasn’t from the cutting tools — with a 100-off stainless job running through the business frequently, Woodbrook set up six vices in a line on the spacious 3.5m bed of its Mazak five-axis VTC800/30SR. When each surface and cycle was completed, an operator would re-set the job to process the next face. With a total of four operations, the process was laborious.

The Ceratizit Tombstone in action on the 3.5m bed Mazak VTC800/30SR

The Ceratizit Tombstone in action on the 3.5m bed Mazak VTC800/30SRMr Hogg spoke with Matt who devised a bespoke workholding solution that was ‘Made in Sheffield’ at the Ceratizit UK Technical Centre and headquarters. When Mr Hogg visited the Ceratizit stand at

MACH 2024, he realised that the only cost for Ceratizit’s bespoke service was the price of the aluminium tombstone billet and the cost of the four ZSG4-125 centric vices that connect to the zero-point single-riser tombstone system. Immediately impressed, Woodbrook Precision ordered a pyramid system to clamp smaller parts in its five-axis Mazak CV5-500.

The ZSG4-125 Centric vices with serrated jaws enabled Woodbrook to clamp on as little as 3mm of stock, permitting the sub-contractor to hit all five sides of the stainless parts with confidence in the high-torque clamping forces of the vice. With five faces machined in a single operation, the following operation was to turn the parts over to complete the sixth surface. This reduced this 100-off repeat job from a four to a two-operation process, saving 10min per part.

Mr Hogg concluded: “This job took over 1hr per part from start to finish. The tombstone and Centric ZSG vices immediately took more than 10min off each part, with peripheral savings being longer running times without operator intervention. Reduced set-ups also improved our precision, repeatability and consistency over an entire batch of parts. Furthermore, we work 12hr a day, six days a week, and the tombstone enabled us to set up a batch of four parts at the end of a shift to run unmanned for 2hr – giving us further savings.

“We are now using Ceratizit for everything from our back-ends and collets to solid carbide and indexable tools — ranging from drills and threadmills to end mills, turning and parting tools. We never thought we would be turning to Ceratizit for our workholding solutions, but just like the cutting tools – the quality and performance of the workholding solutions that come with the ‘Made in Sheffield’ brand is far superior to anything else we have encountered.”