With the introduction of the new double-edged WT26 indexable inserts with compatible turning toolholder system, Bromsgrove-based

Walter GB Ltd can now offer a solution that is perfect for producing small parts on Swiss-type sliding-head turning centres.

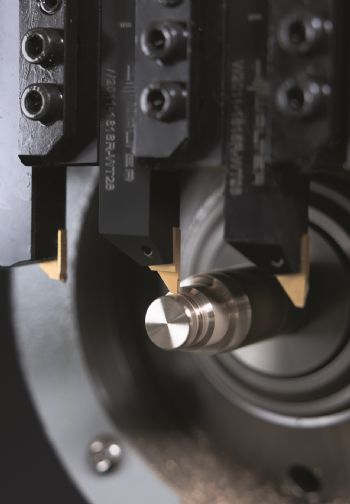

Bars with a diameter below 20mm are typically machined to meet strict precision requirements – this is where the new WT26 system is the ideal solution as the dovetail shape of the insert clamp is excellent at absorbing lateral forces, ensuring high levels of stability, process reliability and accuracy. The clamp system and the large contact surface in the insert seat maximise stability, which particularly counteracts any vibration of the bar material.

Another special feature is the possibility of operation on both sides. This is credit to a clamping screw that has a Torx on both the head side and the threaded side, meaning that it can always be operated from the side of the counter-spindle on right and left-hand tools. This makes it possible to index the inserts quickly without removing the toolholder, significantly reducing non-productive time for the operator.

The tangentially-mounted WT26 indexable inserts are precision-ground and feature sharp cutting edges specifically for turning small precision parts. Furthermore, the periphery ground chip breaker geometries are also available in DG8 and VG8 designations making it possible to achieve optimum machining results even at feed rates from as low as f:0.03mm. Walter’s WT26 indexable inserts are available in seven different versions, covering all turning operations. This includes everything from basic recesses and external threads to reverse turning with specially developed chip breakers.

The new WSM23X cutting tool material is perfect for machining steel, stainless steel and lead-free brass. In addition, the uncoated WN23 grade is suitable for aluminium and non-ferrous metals. Furthermore, the cutting inserts can be used in any WT26 toolholder, regardless of the system, making it an ideal solution for the mass production of small precision parts like pneumatic valves or small electric motors.