At the recent

Formnext 2024 exhibition in Frankfurt,

AM Solutions – 3D post processing technology once again demonstrated its leadership in automated post-processing for additive manufacturing (AM) by unveiling groundbreaking innovations. The company’s renowned 2-in-1 systems also remained a key attraction. The 3-D printers showcased were accompanied by nsights into successful collaborations with industry leaders such as

EOS and

Stratasys, highlighting joint efforts that are shaping the future of AM.

Formnext 2024 confirmed its role as a premier international gathering for the 3-D printing industry and an ideal stage for showcasing innovations in industrial AM. This year underscored the increasing importance of post-processing in making 3-D printing more economical and scalable for series production.

David Soldan, head of AM Solutions – 3-D post processing technology, said: “Automated post-processing is critical for enhancing efficiency, improving quality, and reducing costs per part. Many post-processing steps are still manual, making them time-consuming and costly while limiting reproducibility. Addressing this challenge is key to the industrialisation of AM.

AM Solutions showcased its ability to tackle these challenges with expertise rooted in decades of surface finishing and automation knowledge from

Rösler. The company offers solutions specifically designed for the unique demands of AM underscored by close collaborations with leading 3-D printer manufacturers like HP, Stratasys, and EOS, which rely on AM Solutions’ expertise.

Pictured right: the C1 Max enables a fully automated and user-friendly cleaning process for 3-D printed SLA parts for build platforms of up to 750 x 750 x 550mm

Pictured right: the C1 Max enables a fully automated and user-friendly cleaning process for 3-D printed SLA parts for build platforms of up to 750 x 750 x 550mmIn addition to established systems like the S1 Wet, M4, and C1, AM Solutions unveiled new innovations such as the S1 and S2 space- and cost-saving 2-in-1 solutions. These innovations strengthen AM Solutions’ position as one of the leading providers of post-processing technology and a preferred partner for industrialising 3-D printing.

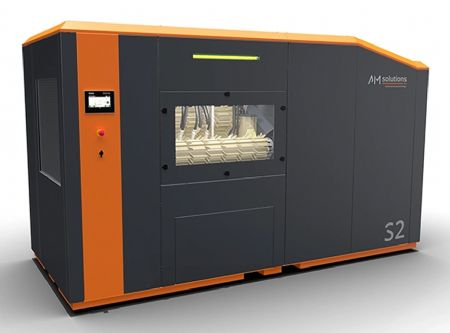

Mr Soldan explained: “We have made a great product even better with the new version of our proven S2.” Customer feedback played a pivotal role in driving improvements to meet market needs. The upgraded S2 achieves a 25% increase in media throughput, thanks to an optimised blasting media circulation system, resulting in greater efficiency and improved surface quality.

At the heart of the updated S2 is the reliable PU continuous loop belt, known for gentle parts handling and consistent blasting performance in continuous operation. The updated design enhances process stability and prevents over-handling of parts. Additionally, the newly integrated drum separation system delivers superior cleaning performance, even with high throughput.

These improvements have already impressed Italian 3-D printing specialist

Weerg, a long-standing user of AM Solutions’ post-processing systems. At

Formnext, Weerg purchased two new S2 systems alongside an additional S1.

Unveiled at

Formnext 2024, the C1 Max builds on the concept of the C1 and was developed in partnership with

Sauber Motorsport to meet the specific demands of large SLA build platforms. SLA-printed parts are submerged in a specially tempered processing fluid via an automated lowering system. A combination of chemical, thermal, and mechanical processes clean the parts and also softens support structures, allowing for their easy and damage-free removal.

The automated solution reduces post-processing time by an impressive 50%, eliminating the need for labour-intensive manual scraping and extensive personal protective equipment. In addition, the C1 Max uses a specially developed process agent that is more environmentally friendly than existing agents. Designed for a build volume of 750 x 750 x 550mm (L x D x H), the system accommodates full platforms from 3-D printers like the 3D Systems ProX 800 and SLA 750. It is also adaptable for other build sizes, such as the Stratasys Neo 800.

Pictured left: the new version of the S2 for the fully automatic cleaning and surface finishing of workpiece batches from powder-based printing processes in 24/7 operation impresses with a 25% increase in media throughput

Pictured left: the new version of the S2 for the fully automatic cleaning and surface finishing of workpiece batches from powder-based printing processes in 24/7 operation impresses with a 25% increase in media throughputThe collaboration between Stratasys and AM Solutions has resulted in an innovative 3-in-1 post-processing system for the Stratasys H350 SAF 3-D printer. The new PowderEase T1 combines depowdering, powder recovery, and powder dosing in a single unit, significantly simplifying workflows, reducing operating costs, and boosting overall productivity. One PowderEase T1 can serve up to six H350 printers, reducing the need for additional equipment and labour. Compared to manual processes, the system saves up to 50min per print job, offering significant time savings.

EOS and AM Solutions have joined forces to advance the SLS post-processing workflow for the EOS P3 NEXT series and beyond. Their collaboration has produced two machine concepts — an unpacking solution that automatically depowders parts economically and reproducibly while minimising operator exposure to powder, and an innovative 2-in-1 system for screening and mixing the powder.

The 2-in-1 system combines these steps in a single machine, saving space and costs. It employs a unique method to produce high-quality blends of new and recycled powder with adjustable mixing ratios, even for small batches. Early results from EOS indicate outstanding performance.