When

Direct Engineering & Site Services Ltd first opened for business in Sheepbridge, it was just a small fabrication shop. Fast-forward 28 years, and the Chesterfield company operates from a 40,000ft

2 premises with five divisions that deliver a wide range of services to customers in the UK and Europe.

The company specialises in the installation of material-handling equipment, vacuum conveying, and chiller pipework systems, and has evolved from a fabrication company, adding services such as machining along the way. Hove-based

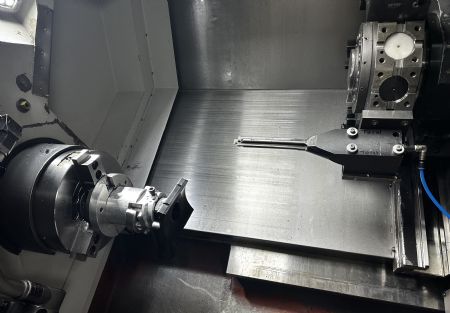

Dugard, a leading machine tool supplier, has supported the company with its wide range of machine tools over the years with the latest acquisition being a Dugard SMEC SL 3000LM turning centre.

Ray Woolley, Direct Engineering’s managing director, said: “We started in 1997 as a fabrication specialist that initially machined on a smaller scale. As time progressed, we saw the need to expand our machining operations as our customers requested more machining services, as well as welding and fabrication. So, we grew on the milling and turning side and invested in CNC machines. We are producing a wide range of parts for industries from marine, automotive, and pharmaceutical to power to the water authorities. We machine everything from plastic, brass, and aluminium to stainless steel, duplex, composites, and more, as we need to offer all the services we can.”

To accommodate this wide variety of materials, the versatility of the Dugard SMEC SL3000LM machine was the ideal choice for the Chesterfield manufacturer. Mr Woolley continued: “Each material has its challenges and how it cuts, but with a wide listing of materials and types of work, Dugard helped us with a machine breakdown and quickly got us up and running. For that reason, we continued our relationship with machine tool supplier. We have had a lot of good productive advice from Dugard on how to best machine this diverse range of materials.”

The latest SMEC SL 3000LM was not the first Dugard machine to arrive at the Derbyshire company. Direct Engineering has a range of Dugard machines, including the SMEC PL2500, PL35 and PL45 turning centres. Discussing the purchase of specific options on its machines, such as steady rests and live tooling, Mr Woolley added: “Having very capable machines has given us much diversity in what jobs can go on what machines. We can also get finished products from the Dugard machines with the live tooling facility. Previously, these jobs may have gone from a turning centre to a milling operation. This means we can now turn products around much more quickly for customers by keeping them on a flexible machine with live tooling.”

Maximising outputDirect Engineering is ISO:9001 and ISO:1090 certified and has increased its plant list from one to four Dugard machines that are all installed in a machine shop with a limited floor area. Mr Woolley explained: “It is a compact machining cell. To maximise our space, we spoke to Colin and Eric at Dugard about what machines are the best fit for our company to maximise our output and they gave us some very constructive advice which has enabled projects to progress through the machine shop very quickly and efficiently, so we appreciate all the support we have had over the years.”

Mr Woolley said: “We started with the largest machine firs which we needed for large billet work. We bought a Dugard SMEC PL45LY for this work, which has a large machining capacity. As we slowly phased out older machines, we invested in the SMEC PL2500 and the PL35, which are also larger machines. Then came our most recent addition, the SMEC SL3000. This has a bar feed and steady rest, which ensures we can cover most applications in this machine shop. The Dugard machines with live axial and radial tooling have enabled us to keep jobs on the machines rather than transferring components to a milling machine. All the Dugard machines have proven to be invaluable.”

He added: “The parts we produce go from small bar fed components that can be manufactured in high volume up to large billet work that can be machined on the Dugard SMEC PL45LY machine. Our parts range from one end of the size scale to the other, and we have got the machines here to accommodate that diversity. Additionally, we are machining to very tight tolerances on some of the shaft work, especially regarding the concentricity required on parts before other finishing operations such as chroming.”

He concluded: “Dugard has provided sound advice on the best machine tool options for our needs. Dugard initially helped us out of a hole when our old machine gave up the ghost and packed up. They have always been there for after-sales service, advising us on the best machine for the application, and also training our new operators. People like Rod at Dugard will happily visit our site and provide training, inform us about the capabilities of the machines and how to utilise them to our best advantage. This level of service has been invaluable for us.”