Rainford Precision Ltd

Rainford Precision Ltd will be demonstrating exactly why the company is widely regarded as an expert in micro-machining at the forthcoming

Manufacturing Solutions Ireland exhibition in Limerick, taking place on 11 and 12 June at the

Technological University of Shannon (TUS) (Stand 8 in the Lobby Zone).

The company will give visitors an insight into its bespoke solutions available for Irish manufacturers and will present technology including the Kern range of ultra-precise five-axis machining centres, Finepart micro-abrasive waterjet cutting technology and cutting tools from some of the world’s most prestigious brands.

Kern is renowned for its unparalleled levels of precision with machine tools that comfortably achieve precision and repeatability levels of +/-1µm during five-axis machining. Rainford Precision will demonstrate the incredible speed, precision and productivity of the Kern machines while discussing the multitude of machine installations and applications at some of the most stringently regulated and precision-driven industries in the manufacturing sector.

Engineers from Rainford Precision will also present the Finepart micro-abrasive waterjet cutting technology. With its three, four, and five-axis waterjet machines, Finepart takes ‘micro’ precision to a new level. It can achieve a positional accuracy of +/-2.5µm, a repeatability of +/-2µm, and a typical cutting tolerance of +/-10µm.

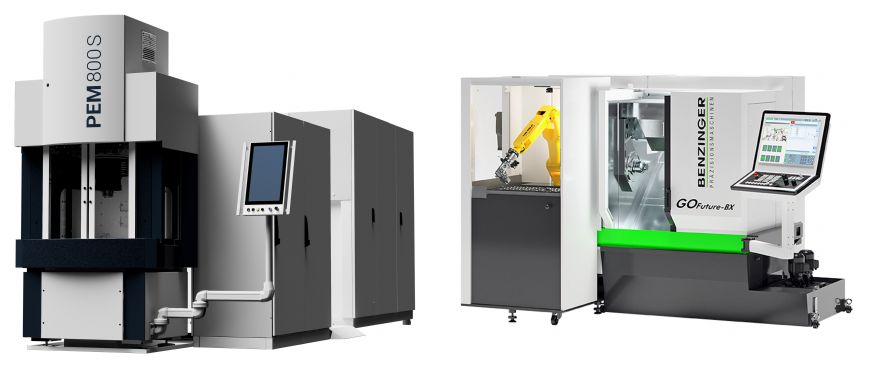

New to the Rainford stable and making its debut in Ireland will be the PEMTec brand. Recognised as a world leader in precision electrochemical metal machining (PECM), this process enables metal parts to be machined with an accuracy and repeatability in the sub-micron range, achieving a surface quality of 0.03µm – all without contact.

Benzinger turning centresMeanwhile, the new

Benzinger range of turning centres will also be showcased on the Rainford stand. As is standard with any Rainford Precision brand, the German Benzinger machines distinguish themselves with remarkable levels of precision, repeatability, productivity, and flexibility.

The company will also present its latest cutting tool solutions from world-renowned brands including Union Tool, Louis Bélet, Delmeco, Gloor, HOBE, Osawa, DTS, Iwata, 6C Tools, Swissceramill and ATOM. The respective partners are industry leaders in the manufacture of drills, end mills, reamers, boring bars, threadmills and slitting saws. Within this diverse portfolio are tools for specialist applications and material types, such as the Hufschmied brand of milling tools.

The Graftor range of end mills from Hufschmied has been developed specifically for machining graphite, and the range can double productivity rates and tool life when compared to rival tools. With such a diverse platform of specialist cutting tools and micro tool solutions, Rainford has invested in a Keyence digital microscope to provide a complete tool investigation and consultancy service for customers in the UK and Ireland.

Rainford Precision’s managing director Miles Evans concluded: “When you are servicing customers with tools below 0.5mm diameter, diagnosing and optimising tool life and performance is a challenge. The Keyence system enables us to provide a unique service within the cutting tool marketplace. At

Manufacturing Solutions Ireland in June, we will be able to discuss the challenges of micromachining and offer manufacturers a solution that wasn’t available before.”