German workholding and handling equipment manufacturer Roemheld, whose subsidiary

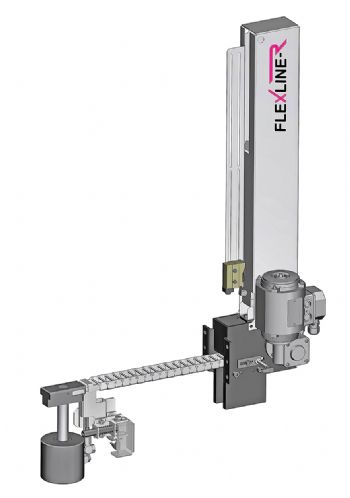

Roemheld UK Ltd is located in Cramlington, has introduced a new, robust, adaptable system for automatically and rapidly clamping dies of various sizes to a press ram. Flexline-R is suitable for quick setups in automated press lines and other applications requiring frequent die changes. Numerous variants can be configured to suit individual customer requirements.

Based on the company’s Flexline system, the new product has been further developed to accommodate higher loads and demanding operating conditions. It is equipped with a stainless steel pull-push chain that replaces the previous plastic version, plus reinforced stops and reliable sensor technology, while offering improved emergency protection. The chain case, all brackets and the sheet metal parts are also made of stainless steel.

Multiple units, commensurate with the weight of the die, are mounted at regular intervals along the face of the ram at the T-slot positions. The electromechanically-driven pull-push chain in each unit automatically moves an integral hollow piston cylinder from the park position to the die edge. Additionally, electric and hydraulic power is delivered to the clamping element via the chain, eliminating the need for a separate energy supply.

Improved position monitoring is a result of having a high-precision magnetic field sensor to detect the die location, while an inductive sensor reports the position of the clamping element on the die. Optionally, the end position of the chain can be verified using a sensor integrated in the chain case. New also are reinforced brackets for position monitoring to ensure maximum operational safety. An emergency release on the drive motor provides additional protection in the event of an accident. If necessary, the die can be released manually.

Flexline-R is available with two adjustment tracks — 660 or 1,100mm long — which defines the length along the press ram’s T-slots that one of four different clamping elements can travel. Depending on requirements, single or double-acting hollow piston cylinders are supplied with up to 104kN clamping force and operating pressures of 245 or 400bar. The unit’s motor can be mounted on the left or right.

Due to its compact design, low weight and the use of low-maintenance modules, Flexline-R is configured to meet the demanding requirements of modern press lines. The modules are easy to replace, simplifying servicing and reducing downtime. The electrical interface is via Harting connectors with IP65 protection.