The Swedish technology company

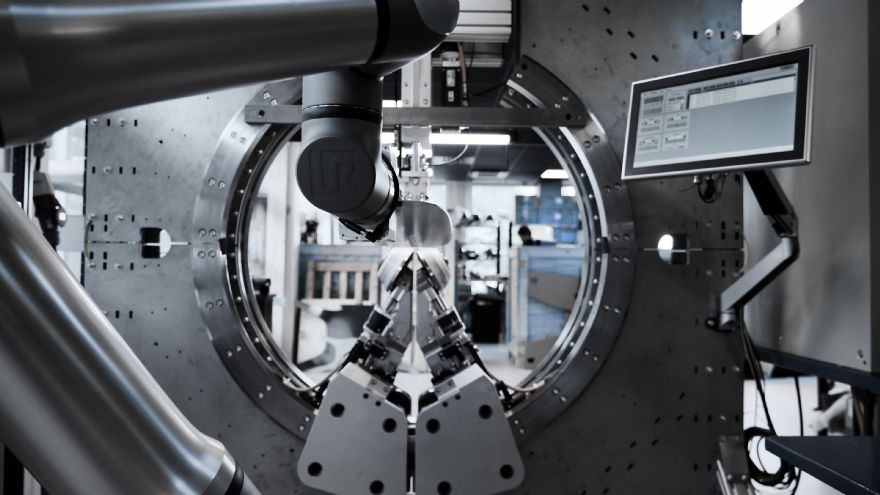

Stilfold has been granted a pan-European patent for a new hardware architecture that enables programmable, fixture-free sheet metal folding along curved, non-linear paths. The company says its system disrupts traditional bending and offers a low-energy high-precision alternative for ‘next-gen structural manufacturing’ in sectors that include automotive, aerospace, architecture — and more.

Stilfold says its patented mechanism enables controlled plastic deformation and “marks a paradigm shift from traditional straight bending, unlocking the ability to create complex, high-performance 3-D geometries from flat material in a single, tool-less fixture-free sequence. By reducing part count, eliminating welding and tooling, and optimising stress distribution, our system offers a low-energy high-precision alternative for structural applications.”

Jonas Nyvang, Stilfold’s CEO and co-founder, said: “This patent secures the core mechanical innovation behind our process. It is a foundational enabler of programmable, robot-compatible metal forming with drastically lower environmental and economic footprint. The capacity to fold metal along non-straight paths unlocks entirely new design and manufacturing strategies.

“Our technology suite, now expanded by this patent, positions the company at the forefront of digital manufacturing in automotive, architecture, aerospace and industrial design, where strength-to-weight optimisation, circularity, and on-demand flexibility are becoming industry imperatives.”